Debulhador de milho fresco | Descascador de milho doce

| Modelo | SL-268 |

| Capacidade | 400-500 kg/hora |

| Peso | 100kg |

| Tamanho (mm) | 700(L)*620(L)*1250(A) |

| Tensão | 220V,1 fase |

| Poder | 2,2 kW |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A debulhadora de milho fresco pode descascar com eficiência milho fresco e cozido, com capacidade de 400-500kg/h, garantindo que os grãos de milho permaneçam intactos e sem danos durante o processo.

Os componentes da debulhadora de milho fresco que entram em contato com o milho são elaborados para atender a rígidos padrões de higiene alimentar, garantindo um processo de debulha limpo e higiênico.

A saída da debulhadora de milho fresco é ideal para embalagens de milho enlatado, suco de milho e produtos congelados, tornando-a uma solução versátil para diversas indústrias de processamento de alimentos.

Vendo debulhador de milho fresco

Peeling requirements:

- O milho deve ser descascado antes da debulha.

- O descascamento pode ser feito manualmente ou com descascador de milho.

- Os bigodes do milho também devem ser retirados antes da debulha para evitar que fiquem nos grãos.

Types of corn:

- Adequado para debulhar todos os tipos de milho, incluindo milho fresco, doce, glutinoso e congelado (após descongelamento).

Production scale:

- Ideal para produção em larga escala em linhas de montagem.

- Também adequado para produção em pequena escala em oficinas familiares.

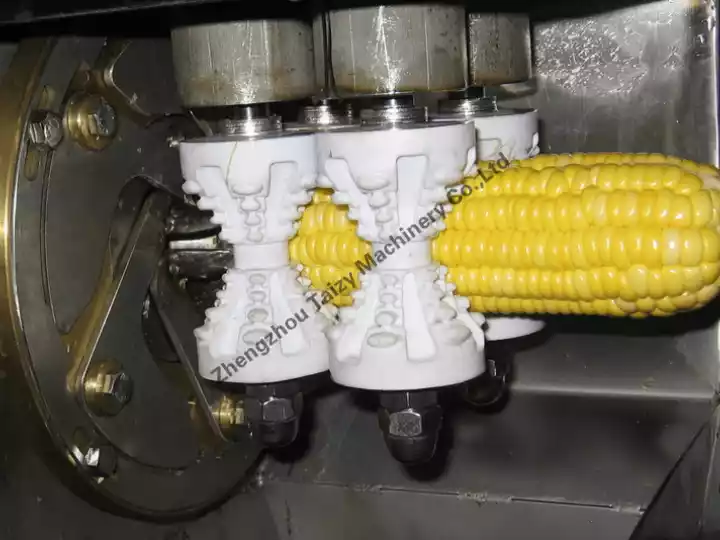

Knife set:

- Apresenta um conjunto de facas de alta qualidade que se ajusta automaticamente com base no tamanho da espiga de milho.

Adjustable threshing:

- A profundidade da debulha é ajustável para atender a diferentes necessidades.

Threshing efficiency:

- Alcança eficiência de debulha de até 99%, garantindo que o milho seja totalmente trilhado sem perda de nutrientes.

Parâmetros da debulhadora de milho doce

| Modelo | SL-268 | SL-368 |

| Capacidade | 400-500 kg/hora | 400-500 kg/hora |

| Peso | 100kg | 110kg |

| Tamanho (mm) | 700(L)*620(L)*1250(A) | 1320(L)*620(L)*1250(A) |

| Tensão | 220V,1 fase | 220V,1 fase |

| Poder | 2,2 kW | 2,2 kW |

Estrutura da máquina debulhadora de milho doce

Freqüência

- Colocação do inversor. Situado dentro da máquina para operação eficiente.

- Velocidade ajustável. A velocidade de trabalho pode ser personalizada com base em requisitos específicos.

Transmissão automática

- Dispositivo de transporte de corrente. Equipado com um sistema de corrente para um funcionamento suave.

- Transporte automático. Permite o manuseio de materiais contínuo e inteligente.

- Aumento de eficiência. Melhora significativamente a eficiência geral do trabalho.

Projeto do soprador

- Equipado com soprador. Garante que o milho seja bem limpo após a debulha.

- Elimina a limpeza secundária. Reduz a necessidade de etapas adicionais de limpeza.

- Economiza tempo e esforço. Aumenta a eficiência ao agilizar o processo.

Painel de controle

- Recursos do painel de controle. Inclui um interruptor, chave reversa e chave de parada.

- Funcionalidade de chave reversa. Permite que o milho se mova para trás se estiver preso, resolvendo bloqueios.

- Operação suave. Garante uma debulha contínua e eficiente da máquina.

Exportação de espiga de milho

- Tamanho de saída ajustável. Adapta-se automaticamente ao tamanho do milho.

- Remoção completa do kernel. Garante que todos os grãos de milho sejam bem trilhados.

- Prevenção de danos. Protege o milho de danos durante a debulha.

Vantagens da debulhadora de milho fresco

- Design bem pensado. Equipado com rodas para movimentos fáceis e flexíveis.

- Rolo de borracha seguro e durável. Feito de material atóxico, macio e elástico para garantir que a casca ultrafina do milho permaneça intacta durante a alimentação, evitando ruptura da pele e transbordamento de conteúdo.

- Ajuste automático de tamanho. Adapta-se ao tamanho do milho, garantindo alta taxa de remoção de grãos de milho.

- Sistema de alimentação eficiente. Utiliza transporte por corrente para alimentação conveniente de milho, aumentando significativamente a eficiência do trabalho.

Um caso de sucesso de nossa debulhadora de milho fresco

Em uma importante empresa agrícola no Canadá, nosso Debulhador de Milho Fresco apresentou resultados excepcionais. A máquina provou ser altamente eficiente na debulha rápida e é especialmente adequada para o gerenciamento de colheitas de milho em grande escala.

Ao melhorar significativamente a eficiência da produção, a máquina ajudou o cliente a reduzir as horas de trabalho durante os períodos de pico da colheita, mantendo ao mesmo tempo uma produção consistente de milho de alta qualidade.

O cliente manifestou grande satisfação com a durabilidade e fiabilidade da máquina, elogiando o seu papel na modernização e agilização das suas operações agrícolas.

Conclusão

In addition to the Fresh Corn Thresher, we offer a wide range of corn processing machines, including corn peelers, corn grinders, and corn flour mills, to meet diverse production needs.

Feel free to contact us for more information or to request a quote. We are here to provide you with the best solutions for your corn processing requirements!