Fresh corn thresher | Sweet corn sheller

| Model | SL-268 |

| Capacity | 400-500kg/h |

| Weight | 100kg |

| Size (mm) | 700(L)*620(W)*1250(H) |

| Voltage | 220V,1 phase |

| Power | 2.2kw |

You can now ask our project managers for technical details

Fresh corn thresher can efficiently shell both fresh and cooked corn, with a capacity of 400-500kg/h, ensuring the corn kernels remain intact and undamaged during the process.

Fresh corn thresher components that come into contact with the corn are crafted to meet strict food hygiene standards, guaranteeing a clean and sanitary threshing process.

Fresh corn thresher output is ideal for packaging in canned corn, corn juice, and frozen products, making it a versatile solution for various food processing industries.

Fresh corn thresher for sale

Peeling requirements:

- Corn must be peeled before threshing.

- Peeling can be done manually or with a corn peeler.

- Corn whiskers must also be removed before threshing to avoid leaving them in the kernels.

Types of corn:

- Suitable for threshing all kinds of corn, including fresh, sweet, glutinous, and frozen corn (after thawing).

Production scale:

- Ideal for large-scale production in assembly lines.

- Also suitable for smaller-scale production in family workshops.

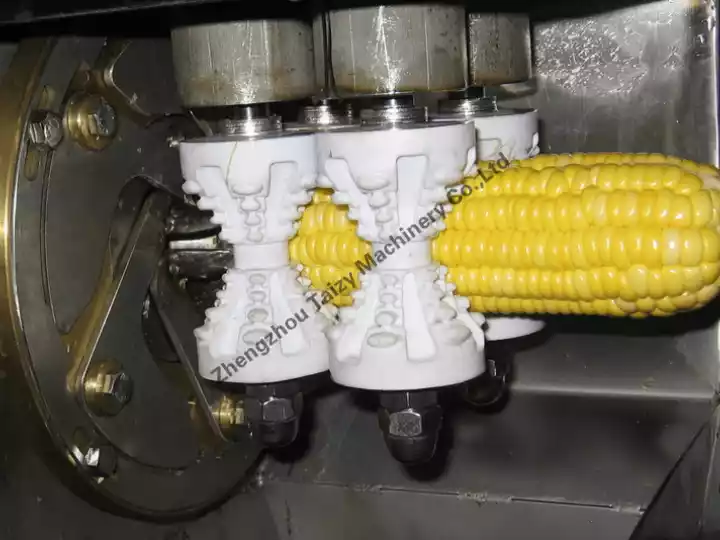

Knife set:

- Features a high-quality knife set that adjusts automatically based on the size of the corn cob.

Adjustable threshing:

- Threshing depth is adjustable to cater to different needs.

Threshing efficiency:

- Achieves up to 99% threshing efficiency, ensuring the corn is completely threshed without losing nutrients.

Parameters of sweet corn thresher

| Model | SL-268 | SL-368 |

| Capacity | 400-500kg/h | 400-500kg/h |

| Weight | 100kg | 110kg |

| Size (mm) | 700(L)*620(W)*1250(H) | 1320(L)*620(W)*1250(H) |

| Voltage | 220V,1 phase | 220V,1 phase |

| Power | 2.2kw | 2.2kw |

Sweet corn thresher machine structure

Frequency

- Inverter placement. Set inside the machine for efficient operation.

- Adjustable speed. Working speed can be customized based on specific requirements.

Automatic transmission

- Chain conveying device. Equipped with a chain system for smooth operation.

- Automatic conveying. Enables seamless and intelligent material handling.

- Efficiency boost. Significantly improves overall work efficiency.

Blower design

- Equipped with a blower. Ensures the corn is thoroughly cleaned after threshing.

- Eliminates secondary cleaning. Reduces the need for additional cleaning steps.

- Saves time and effort. Enhances efficiency by streamlining the process.

Control panel

- Control panel features. Includes a switch, reverse key, and stop key.

- Reverse key functionality. Allows the corn to move backward if stuck, resolving blockages.

- Smooth operation. Ensures continuous and efficient threshing of the machine.

Corn cob export

- Adjustable outlet size. Automatically adapts to the size of the corn.

- Complete kernel removal. Ensures all corn kernels are thoroughly threshed.

- Damage prevention. Protects the corn from harm during threshing.

Advantages of fresh corn thresher

- Thoughtful design. Equipped with wheels for easy and flexible movement.

- Safe and durable rubber roller. Made of non-toxic, soft, and elastic material to ensure the ultra-thin corn peel remains intact during feeding, preventing skin breakage and content overflow.

- Automatic size adjustment. Adapts to the size of the corn, guaranteeing a high removal rate for corn kernels.

- Efficient feeding system. Uses chain conveying for convenient corn feeding, significantly enhancing work efficiency.

A successful case of our fresh corn thresher machine

In a prominent agricultural enterprise in Canada, our Fresh Corn Thresher has delivered exceptional results. The machine has proven to be highly efficient in rapid threshing and is especially adept at managing large-scale corn harvests.

By significantly improving production efficiency, the machine has helped the client reduce labor hours during peak harvest seasons while maintaining a consistently high-quality corn yield.

The customer has expressed great satisfaction with the machine’s durability and reliability, praising its role in modernizing and streamlining their agricultural operations.

Conclusion

In addition to the Fresh Corn Thresher, we offer a wide range of corn processing machines, including corn peelers, corn grinders, and corn flour mills, to meet diverse production needs.

Feel free to contact us for more information or to request a quote. We are here to provide you with the best solutions for your corn processing requirements!