Corn silage harvesting machine

| Capacity | 0.25-0.72hectares/h |

| Harvesting width | 1.3m, 1.5m, 1.65m, 1.8m, 2.0m |

| Length of cruhsed straw | Less than 8cm |

| Stubble height | 8-15cm |

| Fling distance | 3-5m |

| Fling height | ≥2m |

| Recycling rate | ≥80% |

You can now ask our project managers for technical details

Taizy corn silage harvesting machine is designed to crush and collect corn stalks, sorghum stalks, forage grass, and various dry and wet silage materials into pieces smaller than 80mm. Therefore, it is also called straw crushing and recycling machine.

The forage harvester requires a tractor with a power output of ≥70HP. It has working widths of 1.3m, 1.5m, 1.65m, 1.8m, and 2.0m, with a recycling rate of ≥80%. The stubble height ranges from 8 to 15cm, and the working efficiency is 0.25-0.72 hectares per hour.

Highlights of the forage harvester

- Our silage harvester machine is powered by the tractor, eliminating the need for an additional power system, making it suitable for various agricultural environments and offering flexible operation.

- Taizy corn silage harvesting machine integrates straw crushing and collecting, directly collecting the crushed silage into the collection basket, improving field operation efficiency.

- Our silage harvester can operate continuously with high efficiency (0.25-0.72 hectares/h), making it suitable for long-term use in large-scale farmlands.

- We offer various models of forage harvesters, allowing users to choose the appropriate model based on field size and desired operating efficiency to improve overall operational benefits.

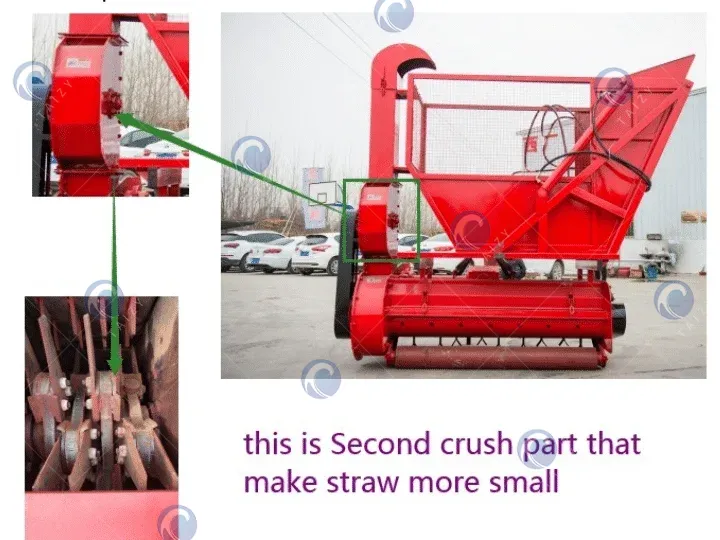

- Taizy straw crushing and recycling machine can be equipped with a second crushing component to achieve finer straw shredding, facilitating subsequent straw recycling and utilization.

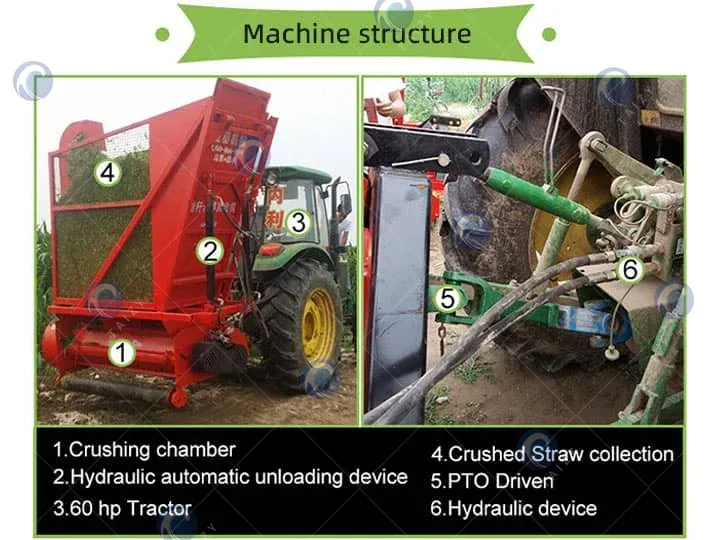

Structure of forage harvesting machine

Taizy corn silage harvesting machine features a well-designed overall structure, mainly composed of crushing chamber, crushed straw collection device, hydraulic automatic unloading device, hydraulic system, and PTO drive system.

Working principle of forage harvester machine

The corn silage harvesting machine utilizes the output power of the tractor power output shaft, and transmits the power to the recycling machine through the universal joint. The recycling machine utilizes gear shifting and V-belt transmission to drive the shaft to rotate at high speed to cut the straw.

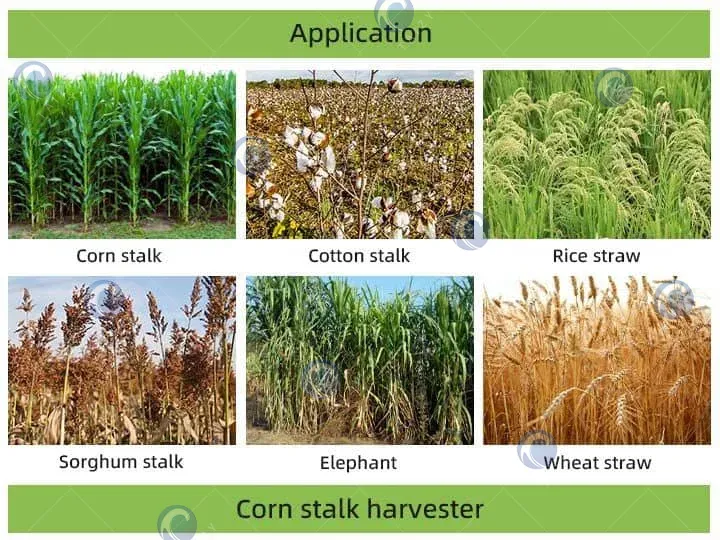

Application of corn silage harvesting machine

Our forage harvester machine is suitable for harvesting and collecting the straw of various crops, including rice, corn, sorghum, soybeans, cotton, rapeseed, and both dry and wet silage. It can meet the straw recycling needs of different regions and crop types.

Technical parameters of the corn silage harvester

The table below lists the main technical parameters of the corn silage harvesting machine, for users to refer to before selection and use.

| Model | 4JQH-135 | 4JQH-150 | 4JQH-165 | 4JQH-180 | 4JQH-200 |

| Tractor | ≥70HP | ≥75HP | ≥90HP | ≥100HP | ≥110HP |

| Dimension | 1500*1810*3350mm | 1480*1980*3500mm | 1480*2130*3500mm | 1480*2280*3500mm | 1680*2460*3350mm |

| Weight | 640kg | 700kg | 790kg | 980kg | 1000kg |

| Harvesting width | 1.3m | 1.5m | 1.65m | 1.8m | 2.0m |

| Recycling rate | ≥80% | ≥80% | ≥80% | ≥80% | ≥80% |

| Fling distance | 3-5m | 3-5m | 3-5m | 3-5m | 3-5m |

| Fling height | ≥2m | ≥2m | ≥2m | ≥2m | ≥2m |

| Length of cruhsed straw | <8cm | <8cm | <8cm | <8cm | <8cm |

| Stubble height | 8-15cm | 8-15cm | 8-15cm | 8-15cm | 8-15cm |

| Roating blade | 32 | 40 | 44 | 48 | 52 |

| Cutter shaft speed | 2160r/min | 2160r/min | 2160r/min | 2160r/min | 2160r/min |

| Working speed | 2-4km/h | 3-4km/h | 3-4km/h | 3-4km/h | 3-4km/h |

| Capacity | 0.25-0.48hectares/h | 0.3-0.5hectares/h | 0.32-0.55hectares/h | 0.36-0.6hectares/h | 0.36-0.72hectares/h |

Customizable options for forage harvester

1. Collecting basket

Customers can choose whether or not to equiped collection bin based on their needs. Our storage containers have a capacity of 3m³ and can hold 1000 kilograms of material, and can be customized according to customer requirements.

2. Big wheels

Typically, the corn silage harvesting machine do not have wheels. However, if you want the straw to regrow, we can equip the silage cruhsing and collecting machine with suitable tires to maintain the cutting height at an appropriate level.

3. Secondary crushing section

We can also add a secondary crushing device according to customer requirements. The secondary crushing function allows the straw to be crushed into smaller pieces, facilitating its subsequent recycling and utilization, such as in feed processing or biomass treatment.

Price of corn straw harvesting machine

The price of corn silage harvesting machine is determined by several factors, mainly including the following:

- Working efficiency: High-speed crushing structures and reinforced transmission systems configured for efficient operation will affect the overall price of the machine.

- Configuration level: Different configurations, such as whether it includes a hydraulic automatic unloading device or a secondary crushing device, will result in different costs.

- Power matching: Different required tractor horsepower will place different demands on the transmission system and overall structure.

- Customization requirements: Personalized configurations based on different operating conditions will affect the final price to a certain extent.

FAQ of silage crushing and collecting machine

What functions does the machine have?

Straw crushing and recycling function.

Can I purchase only the crushed portion?

Yes, and the price will also be cheaper.

What is the typical lifting height of the machine’s hopper?

3.5 meters above the ground.

Can it process dry straw?

Yes, it can be used for both wet and dry applications.

What is the height of the remaining stubble after crushing?

8-15 cm (adjustable according to requirements).

Contact us for silage processing solutions!

In addition to the corn silage harvesting machine, we also offer high-efficiency silage baler machine that can be used in conjunction with it, enabling integrated operations of silage crushing, collecting, baling, and wrapping. If you have any needs, please feel to contact us for customized silage processing solutions.