Corn peeling and threshing machine | maize shelling machine

| Power | Diesel engine, gasoline engine, electric motor |

| Capacity | 1.5-2t/h |

| Weight | 112kg |

| Size | 1150*860*1160mm |

| Application | Sorghum, Millets, Maize, Soybean |

| Model | 10-12HP diesel engine |

| Capacity | |

| corn 3t/h, Soybean 2t/h Sorghum, Millets, Wheat, Rice 1.5t/h | |

| Weight | 200kg |

| Size | 2100*1700*1400mm |

| Application | Sorghum, Millets, Maize, Soybean |

You can now ask our project managers for technical details

The corn peeling and threshing machine is a machine that can perform two functions corn peeling and shelling. It is a multi-functional corn threshing machine with more comprehensive functions and a more efficient machine. And the corn thresher is also suitable for other grains, such as wheat, sorghum, and soybean crops. It is a machine that is very worthwhile for farmers to buy. This machine has been sold in Finland, Kazakhstan, Dubai, Morocco, the Philippines, Brazil, and other countries.

What are the functions of the multifunctional corn thresher

This Corn peeling and threshing machine is a machine that can perform two functions of corn peeling and threshing and it can add functions at the same time. It can get corn kernels in one processing and does not need to be transported many times. In addition, this corn thresher can not only thresh corn but also thresh other millets such as rice, millet, wheat, soybeans, etc.

How to realize the processing of multiple grains

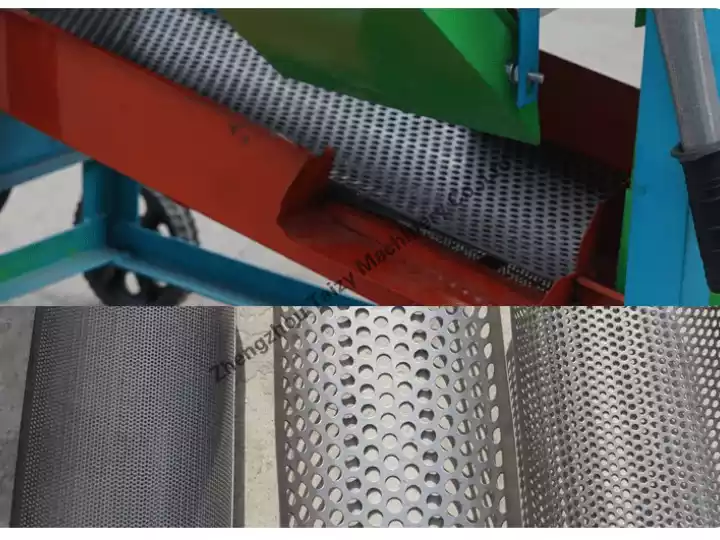

Since the size of each grain is very different, the size of corn kernels and millet are not the same. If you want to process a variety of grains, you need to change the screen of the machine. This will ensure that when the multifunctional thresher is sifting the grain, the grain will not be leaked due to the oversized mesh. Our factory also has various machines such as a fresh corn thresher and corn thresher for processing corn threshing.

Production efficiency of corn peeling and threshing machine

The corn peeling and threshing machine have a threshing rate of up to 95% and a low breakage rate. 1.5-2t per hour. After using this corn peeling thresher, two types of corn can be processed at the same time. However, this corn thresher is processed sun-dried corn and cannot be used directly after the corn is harvested. It needs to be dried to remove the corn moisture. After processing, if the corn is harvested later and the moisture in the cob has evaporated, it can be processed directly. Alternatively, if you want to thresh fresh corn, you can use a sweet corn thresher.

Parameters of corn peeling and threshing machine

| Model | Power | Capacity | Weight | Size | Application |

| MT-860 | Diesel engine, gasoline engine, electric motor | 1.5-2t/h | 112kg | 1150*860*1160mm | Sorghum, Millets, Maize, Soybean |

| MT-1200 | 10-12HP diesel engine | corn 3t/h, Soybean 2t/h Sorghum, Millets, Wheat, Rice 1.5t/h | 200kg | 2100*1700*1400mm | Sorghum, Millets, Maize, Soybean |

Various power modes of corn peeling thresher

We can be matched with diesel engines, gasoline engines, or electric motors as power units. We can customize the machine according to your needs. This is for customers to choose a multi-functional corn thresher that is more suitable for them.

Structure of corn peeling thresher

The thresher is composed of a feed port, a corn kernel discharge port, an impurity outlet, an induced draft fan, a movable wheel, and a screen. One thing to note is that this small thresher has a single fan and a double fan. For machines with dual fans, the corn after threshing is cleaner. After the corn cobs are fed into the feed port, they first enter the peeling box, and after peeling, they automatically enter the threshing box for threshing.

How to use corn peeling and threshing machine

- Before starting the machine, check whether the connecting parts of each key part are firm

- when the machine is running, it is strictly forbidden to open the safety cover.

- if any abnormal situation is found, it must be stopped immediately for inspection, and it is strictly forbidden to troubleshoot the machine when it is running

- when the feeding port is blocked, it is strictly forbidden to use hands or sticks to help feed.

- it is strictly forbidden to mix stones, metals, and other sundries into raw materials.

- please idle for 2-3 minutes before starting the machine to confirm that there is no abnormal phenomenon before starting the operation.

Advantages of multifunctional corn thresher

- Increase the feed inlet. An enlarged feed opening makes it easier to pour with bags and other tools.

- Added filter function. After the corn is threshed, it will be screened to remove some impurities, and the corn will be cleaner after it is detached.

- With wind adjustment function. The thresher adjusts different wind sizes while threshing different incentives