Corn grits machine | Maize grinding machine

| Model | T1 |

| Corn peeling | 350-450kg/h |

| Making corn grits | 1000kg |

| Voltage | 380v |

| Power | 7.5kw |

| Making corn flour | 350kg |

| Spindle speed | 1150r/min |

You can now ask our project managers for technical details

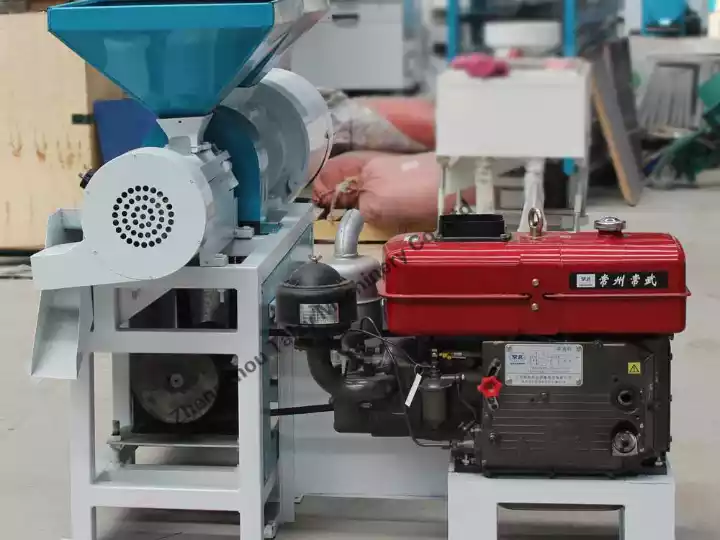

The corn grits machine can process corn kernels into corn grits and corn flour, essential components of daily diets due to their ease of consumption and digestion. It is equipped with dual motors for simultaneous peeling and grit-making, enhancing productivity.

Notably, this machine can also process grains like millet, rice, and sorghum, making it a highly practical choice for modern grain processing. The adjustable finished product ratio further adds to its flexibility, allowing for customized output.

With a capacity of 350-400 kg/h, this machine is ideal for small-scale workshops and larger operations alike. Contact us for more details!

Wide application of corn grinding machine

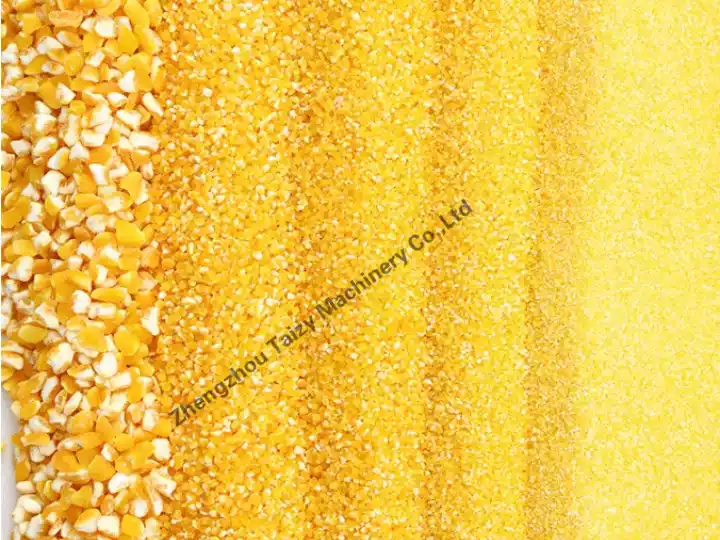

- Corn grits are made by processing corn kernels through a corn grits machine, breaking them into smaller particles.

- The processed corn can also be ground into fine corn flour, depending on the application.

- Corn grits are commonly used in food production due to their versatility and nutritional benefits.

- Additionally, corn grits have applications in the chemical and pharmaceutical industries, where they serve as raw materials for various processes.

Preparing the corn for grinding

Wet dehulling is an effective method for peeling corn, and it is essential to keep the corn’s moisture level below 15%. Here’s how to achieve the best results.

- Moisture adjustment:

- Mix 6 to 8 parts of water with 100 parts of corn. Stir thoroughly to ensure even moisture distribution and eliminate excess water.

- Machine operation:

- During spring and autumn, run the machine for 5 to 6 minutes.

- In winter, increase the operating time to 10 to 12 minutes due to the lower temperature.

Tips for efficient operation:

- Remove the machine’s knives and adjust the roller gap to 3 to 5 mm for optimal performance.

- Alternatively, use a drying net to remove excess moisture from the corn before processing.

Corn grits production

During the corn grits production process, the machine separates the output into three types:

- Corn flour

- Large grits

- Medium grits

Maize grinding machine parameter

| Model | T1 |

| Corn peeling | 350-450kg/h |

| Making corn grits | 1000kg |

| Rated voltage | 380v |

| Power | 7.5 kW 4 pole |

| Making corn flour | 350kg |

| Spindle speed | 1150r/min |

The process of making corn grits

1. Peeled part

- Corn husks and finished product. The husks play a crucial role in determining the quality of the corn grits and are integral to the overall processing of corn.

- Corn peeling benefits. Peeling removes black spots and bran from the corn, enhancing the quality of the final product.

- Clean and smooth surface. The removal of husks ensures that the corn grits have a clean and smooth surface, improving both appearance and texture.

2. Broken part

- Corn crushing function. The corn crushing part is designed to break down corn kernels into smaller granules of varying sizes.

- Three types of finished products. The machine can produce three different types of finished products: corn kernels, corn grits, and corn flour.

- Versatility in processing. The ability to create multiple products from a single process increases the versatility of the corn processing machine.

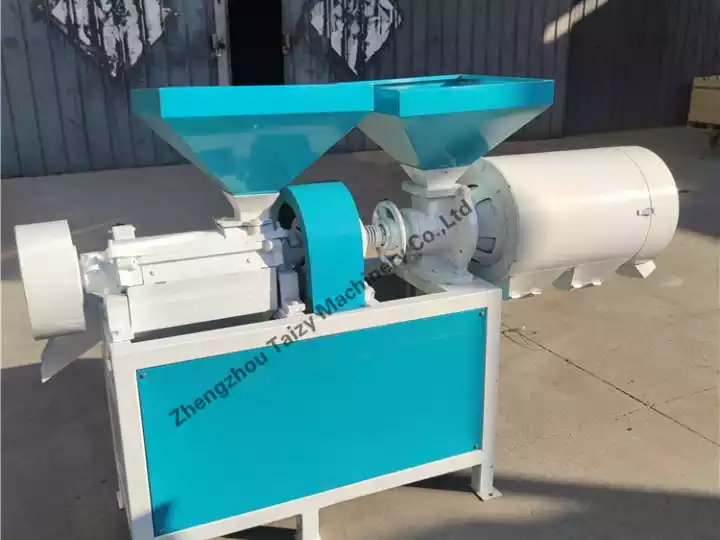

Structure of corn grits machine

The corn grits-making machine has three discharge ports for the feeding buckle and the discharge port for corn husks.

How does the corn grits machine work?

The corn grits machine is a comprehensive primary processing machine designed for corn. It combines several systems to efficiently process corn kernels into various finished products. Here’s a breakdown of how it works:

- Peeling system. Corn kernels enter the hopper, where the peeling process begins. The rotating action of the propeller shaft pushes the corn through the machine, allowing the removal of husks and other unwanted materials.

- Crushing system. As the corn passes through the peeling chamber, the volume of the working chamber is reduced. This increased density helps in the crushing process. The drum continuously flips and propels the kernels, breaking them into smaller particles.

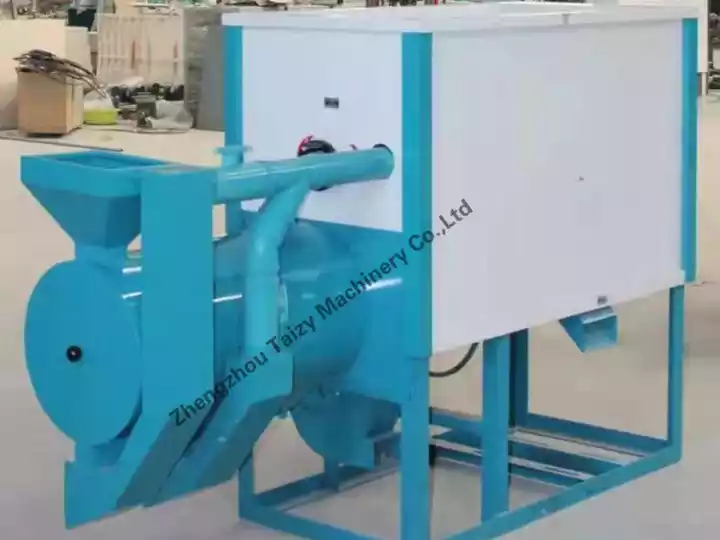

- Grading system. After the crushing process, the corn is sorted into different sizes, resulting in the production of corn grits, corn kernels, and corn flour.

- Dust removal system. The dust removal system ensures that the air inside the machine remains clean and that the final product is free from excess dust.

By incorporating these systems, the corn grits machine effectively transforms raw corn into various processed products with high efficiency.

Corn grits making machine advantages

- Clean, high-quality output. The machine effectively removes black spots and impurities, ensuring clean corn flour and high-quality grits.

- Versatile operation. It can process both wet and dry corn, offering flexibility for different production needs.

- Adjustable fineness and ratios. The machine allows for easy adjustments of the grits’ fineness and the grits-to-cornmeal ratio to meet specific requirements.

- Efficient impurity removal. A unique design accelerates impurity removal, improving processing speed and performance.

- Real-time monitoring. The current display system enables monitoring of internal pressure and peeling efficiency, ensuring optimal performance.

- Automatic adjustment for efficiency. The automatic adjustment and power distribution systems maintain the machine in its best working condition, reducing manual intervention.

- Multi-grain processing. It can also process rice, wheat, and sorghum, expanding its versatility for various grains.

- Time and labor saving. Designed to improve efficiency, the machine reduces labor and processing time while ensuring high cleanliness and bright product color.

How to use the corn grits making machine?

- Moisten the corn. Add about 3 parts of water for every 100 parts of corn and let it sit for about 10 minutes.

- Load the corn into the peeling bin. After moistening, pour the corn into the peeling bin, adjust the peeling pressure handle, and open the feeding bin to start.

- Peeling process. The peeled corn will be unloaded from the front port, while husks and other debris fall naturally from the rear unloading port.

- Crushing the corn. Transfer the dehulled corn to the crushing bin, adjust the crushing handle to the desired particle size.

- Exporting the finished product. The machine will produce three types of granules: large grits, small grits, and corn flour. These will be discharged through the output port.

Invest in our corn girts machine

- Exceptional performance. Built with top-tier craftsmanship and advanced technology for efficient operation.

- Ongoing innovation. We continuously improve our machines to enhance production efficiency and product quality.

- Reliable solution. A dependable machine that supports business growth with stable, high-quality grinding.

- Customer-focused support. We offer attentive after-sales service to ensure continued satisfaction and support.

Contact us

Feel free to contact our sales team for more detailed information and customized solutions. We look forward to collaborating with you to achieve success!