Corn grain mill machine | Maize flour mill machine

| Model | 9FQ-50 Hammer Mill |

| Speed | 3200r/min |

| Rotor diameter | 500mm |

| Screen size (mm) | 690×250 |

| Productivity | ≥1000kg/h |

| Hammer piece | 16 |

| Back teeth (pieces) | 3 |

| Electricity consumption per ton of material | ≤11KW.h/t |

| Voltage | 380V |

| Rated power | 15kw |

| Accessories | Inlet and Outlet Hopper |

| Dimensions (mm) | 1230x1020x1150 |

| Packing size (mm) | 680x720x930 |

| Weight | 160kg |

A corn grain mill machine is a machine used to grind grains into powder. Corn is a frequently processed raw material, and it can be processed into a 0.2-8mm ultra-fine powder. Corn mills are widely used in the food processing industry and the pharmaceutical industry.

This corn grinder can use diesel engines, electric motors, and gasoline engines. In addition to this small corn mill, there are also large corn mills.

Raw materials for corn grain mill machine

This versatility makes the corn mill an indispensable tool in the grain processing industry. Whether processing corn, wheat, soybeans, dried peppers, sorghum, medicinal materials, or other raw materials, or crushing low-hardness minerals such as gypsum, talcum powder, rare earth, chemicals, and clay, it excels effortlessly.

Whether you need to produce food, pharmaceuticals, or chemical products, the corn mill can provide reliable processing solutions, grinding grains and herbs into fine powders to meet your diverse needs.

Structure of corn mill machine

The claw crusher mainly includes six parts: upper body, cover, rotor assembly, screen, feeding device, and frame.

The body and the rotor assembly together form the crushing cavity, and the rotor assembly becomes the main working part. The crushing of the material is completed in the crushing chamber.

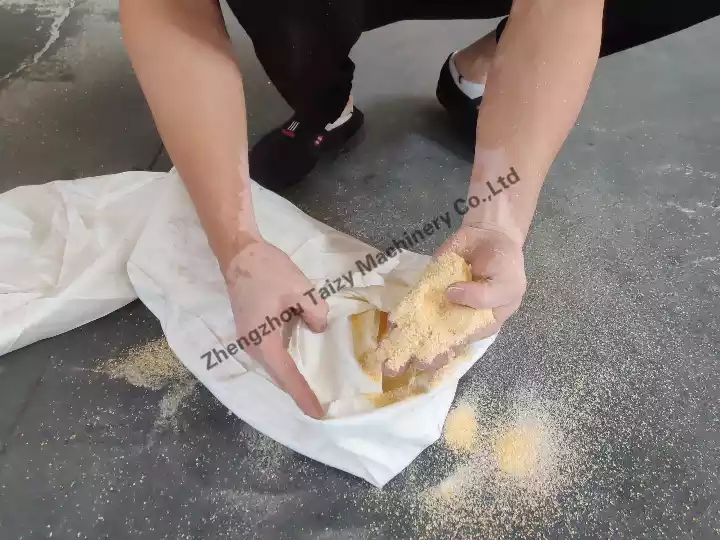

Our corn mill can produce corn flour of 0.2-8mm, and corn flour of different fineness is composed of different sieves

Two Types of maize flour mill machine

The functionalities of both mills are identical, differing only in their feeding mechanisms. One model offers self-priming and automated feeding, providing enhanced convenience.

Conversely, the other necessitates manual feeding, requiring users to evenly distribute corn directly into the machine at a controlled pace. Upon setup, users simply connect a container to the machine’s outlet to collect processed material efficiently.

While the feeding and discharge methods vary between the two machines, their core functionalities remain consistent.

How does a corn grain mill machine work?

During operation, the material intended for processing enters the crushing chamber through the hopper, where it encounters the high-speed rotating components that initiate the crushing process while redirecting the material’s trajectory.

The high-speed rotation disrupts material layer deposition, facilitating its movement alongside the rotor. Throughout this process, particles undergo repeated collisions with both the working components and each other, gradually reducing their size until they pass through the sieve holes.

Under the influence of centrifugal force and airflow, particles are further pulverized. Eventually, the material passes through the sieve holes, enters the crushing chamber, and exits through the discharge port.

The pulverization fineness in such machines is dictated by the size of the sieve holes, allowing users to select screens accordingly based on their desired particle size requirements for the feed.

Maize flour mill machine parameter

Auxiliary feeding corn mill machine

| Model | 9FZ-45 |

| Rotating speed | 3200r/min |

| Rotor diameter | 450mm |

| Diameter of sieve ring | 508mm |

| Screen size (mm) | 1600×115 |

| Productivity | ≥1500kg/h |

| Flat teeth (pieces) | 6 |

| Square teeth (pieces) | 12 |

| Voltage | 380V |

| Weight | 200kg |

Automatic suction-type corn mill

| Model | 9FQ-50 Hammer Mill |

| Speed | 3200r/min |

| Rotor diameter | 500mm |

| Screen size (mm) | 690×250 |

| Productivity | ≥1000kg/h |

| Hammer piece | 16 |

| Back teeth (pieces) | 3 |

| Electricity consumption per ton of material | ≤11KW.h/t |

| Voltage | 380V |

| Rated power | 15kw |

| Accessories | Inlet and Outlet Hopper |

| Dimensions (mm) | 1230x1020x1150 |

| Packing size (mm) | 680x720x930 |

| Weight | 160kg |

Corn grain mill machine advantages

- High-Quality Hammer: Crafted from manganese steel, the hammer boasts exceptional wear and impact resistance, ensuring superior crushing performance.

- Efficient Dust Removal: The corn pulverizer features an advanced dust removal system, promoting a clean and hygienic production environment by minimizing noise and pollution.

- Whisper-Quiet Operation: Utilizing innovative design, the corn mill operates with remarkably low noise levels, fostering an optimal production environment conducive to productivity and comfort.

Contact us

Corn grain mill machines are the cornerstone of efficiency and precision in grain processing, offering unparalleled reliability and performance. With their robust construction and advanced technology, these machines ensure optimal grain milling operations for various applications.

Investing in a corn grain mill machine not only guarantees superior quality end products but also maximizes productivity while minimizing operational costs.

Don’t miss out on the opportunity to elevate your grain processing capabilities and streamline your operations. Contact us now for inquiries and take the first step towards enhancing your business’s success and profitability.