9FQ hammer mill machine | Corn grinder machine

| Model | 9FQ-750 |

| Power (kW) | 22-30 |

| Weight(kg) | 850 |

| Capacity(kg/h) | 1500 |

| Hammer | 32pcs |

| Dia of sieve | 1.2-3mm |

| Package size (mm) | 1500*1000*1600 |

| Installation size (mm )with cyclone and motor | 2000*1200*2300 |

You can now ask our project managers for technical details

The 9FQ Hammer Mill Machine series offers an effective and adaptable solution for grain processing, accommodating capacities ranging from 100 to 3000 kg/h to suit a wide variety of applications.

Equipped with optional cyclone dust collection systems for enhanced efficiency and available with diesel or electric engines, these machines excel in areas with limited electricity access.

Adjustable sieves allow for customized particle sizes, making the 9FQ Hammer Mill ideal for processing grains like corn and soybean meal in flour mills, family stores, and agricultural businesses.

Hammer mill machine application

Versatile applications

- Crush various grains to make flour, including corn, wheat, and soybeans.

- Use on farms to produce feed for cattle and sheep.

- Process additional crops like peanut shells, forage, and straw.

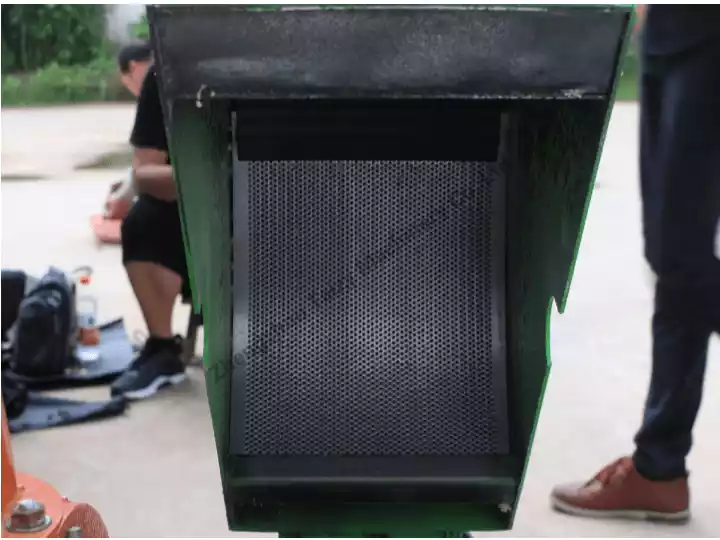

Key feature – replaceable screen

- This flexibility allows the machine to perform multiple functions effectively.

- The machine’s versatility stems from its replaceable screen, which determines the range of materials it can process.

9FQ hammer mill machine fineness of corn

Crushing capacity:

- Reduces raw materials to less than 5cm.

- Processes a wide range of raw materials into various grain sizes, such as 1mm-3cm, 4cm, and 5cm.

Crushing mechanism:

- Materials are fed through the feeding port into the crushing cavity.

- The rotating shaft and high-speed hammer work together to quickly crush the material.

Fineness sorting:

- Crushed materials meeting the desired fineness pass through the screen and are discharged.

- Larger particles continue circulating with the airflow until they are finely ground to the required size.

9fq hammer mill machine structure

- Main components:

- Feeding device shell.

- Rotating shaft with attached hammers.

- Screens for controlling material size and fineness.

- Wear-resistant parts for durability.

- Induced draft fan that doubles as the discharge port.

- Crushing mechanism:

- The crushing cavity includes:

- One main shaft.

- Four matching shafts attached to the main shaft.

- 14 hammers per small shaft, totaling 56 hammers.

- The crushing cavity includes:

- Material fineness control:

- A screen located beneath the rotating shaft determines the size and fineness of discharged materials.

- High-speed discharge system:

- The induced draft fan facilitates the expulsion of crushed materials (e.g., sawdust particles).

- The high-speed operation ensures efficient material output.

9FQ hammer mill machine details

Wear-resistant hammer

Using thickened carbon steel quenching treatment technology, strong and durable, it is 4 times the life of ordinary hammers.

All copper motor

High-temperature copper wire is durable and full of power.

Increase the inlet

Strong and durable, easy to feed.

Precision welding

The factory has 20 years of professional welding technology, fine workmanship, and no leakage.

Working video of hammer mill machine

Corn grinder machine parameters

| Model | Power (kW) | Power(HP) | Weight(kg) | Capacity(kg/h) | Hammer | Dia of sieve | Package size (mm) | Installation size (mm )with cyclone and motor |

| 9FQ-320 | 2.2 | 5 | 50 | 100 | 16pcs | 0.5-5mm | 500*300*600 | 500*300*600 |

| 9FQ-360 | 5.5 | 8 | 120 | 150 | 24pcs | 0.5-5mm | 1100*600*1200 | 1500*1000*1900 |

| 9FQ-420 | 11 | 15 | 200 | 300 | 24pcs | 1.2-3mm | 1200*800*1900 | 1500*1000*1900 |

| 9FQ-500 | 11 | 20 | 300 | 500 | 24pcs | 1.2-3mm | 1200*800*1300 | 1500*1000*1900 |

| 9FQ-600 | 18.5-22 | 30 | 500 | 1000 | 32pcs | 1.2-3mm | 1500*900*1500 | 2000*1100*2300 |

| 9FQ-750 | 22-30 | 35 | 850 | 1500 | 32pcs | 1.2-3mm | 1500*1000*1600 | 2000*1200*2300 |

| 9FQ-800 | 37 | 45 | 1000 | 2000 | 40pcs | 1.2-5mm | 1500*1200*1600 | 2000*1300*2300 |

| 9FQ-1000 | 45-55 | 75 | 1200 | 3000 | 64pcs | 1.2-5mm | 1500*1300*1800 | 2000*1400*2300 |

9FQ hammer mill machine advantages

Energy efficiency:

- Consumes less energy compared to disk mill machines, as the power engine only drives the hammers instead of an abrasive disk.

Lightweight and efficient:

- Designed for high working efficiency while maintaining a compact and lightweight structure.

Versatility in raw materials:

- Corn cobs and kernels.

- Sliced potato or breadfruit from Africa.

Easy sieve replacement:

- Comprehensive instructional video and multiple sieve sizes provided to meet customer requirements.

- Features easily replaceable sieves to control output size.

Mobility and flexibility:

- Can be moved, landed, or fixed according to operational requirements.

User-friendly operation:

- Simple to use, allowing one person to efficiently handle grain crushing tasks.

Enhanced safety features:

- Equipped with a safety cover for secure operation, ensuring safe and confident production.

Price of the corn grinder machine

The pricing of a corn grinding machine reflects its customizable nature and adaptability to various operational needs. Factors such as machine capacity, type of engine (diesel or electric), additional features, and sieve sizes contribute to its price range.

At our company, we understand the importance of tailored solutions and encourage customers to contact us for pricing details. By sharing your specific requirements, we can provide personalized recommendations and ensure you find a machine that meets your needs efficiently. Feel free to reach out for a customized quote and expert guidance!

Conclusion

Committed to delivering top-notch quality, our maize grinder machine stands as a testament to efficiency, convenience, and low power consumption.

We take great pride in welcoming inquiries and purchases from customers across diverse sectors. This high-performing and user-friendly equipment is an indispensable tool in your maize processing workflow.

As part of our product line, we also provide other maize machines such as corn grits making machine and corn flour milling machine. Feel free to consult our professional team at any time to obtain detailed information about our products.