मक्का बोने की मशीन | मक्का बोने की मशीन

| नमूना | 2BYSF-6 |

| आकार | 1.62*3.35*1.2मी |

| पंक्ति | 6 |

| पंक्ति रिक्ति | 428-570 मिमी |

| पौधों का अंतर | 140मिमी-280मिमी |

| गहरी खाई | 60-80 मिमी |

| निषेचन गहराई | 60-80 मिमी |

| बुआई की गहराई | 30-50 मिमी |

| उर्वरक टैंक की क्षमता | 18.75L x6 |

| सीडबॉक्स की क्षमता | 8.5एल x 6 |

| वज़न | 425 किग्रा |

| मिलान शक्ति | 50-80hp |

| कड़ी | 3-उठाई |

अब आप तकनीकी विवरण के लिए हमारे परियोजना प्रबंधकों से पूछ सकते हैं

मक्का बुआई मशीन मक्का, मूंगफली, सोयाबीन, कपास और अन्य सहित विभिन्न प्रकार की फसलें बो सकती है। 12 से 100 हॉर्स पावर तक के ट्रैक्टरों के साथ संगत, यह एक ही ऑपरेशन में नाली बनाने, खाद डालने, बीज बोने, मिट्टी डालने और मिट्टी दबाने जैसी बहुक्रियाशील क्षमताएं प्रदान करता है।

खुदाई की गहराई 60-80 मिमी तक होती है, जबकि बुआई की गहराई 30-50 मिमी होती है, जिससे अंकुरण के लिए इष्टतम बीज स्थान सुनिश्चित होता है। हम 2-पंक्ति, 3-पंक्ति, 4-पंक्ति, 5-पंक्ति, 6-पंक्ति और 8-पंक्ति मकई सीडर्स सहित कई मॉडलों में विशेषज्ञ हैं, प्रत्येक को विशिष्ट कृषि आवश्यकताओं को पूरा करने के लिए तैयार किया गया है।

यह बड़े पैमाने पर बुआई के लिए बहुत उपयुक्त है, और पंक्ति रिक्ति और पौधों की दूरी समायोज्य है, इसलिए इसमें अनुप्रयोगों की एक विस्तृत श्रृंखला और उच्च बीज उद्भव दर है। जानें कि कैसे हमारा मकई बोने वाला यंत्र आपकी रोपण प्रक्रिया को सुव्यवस्थित कर सकता है और कृषि उत्पादकता को अधिकतम कर सकता है।

मक्का बोने वाला कौन सी फसल लगा सकता है?

मकई के अलावा, मकई बोने वाला सोयाबीन, कपास, अनाज, सब्जियाँ और अन्य फसलें भी बो सकता है।

चूंकि प्रत्येक फसल की कतार की दूरी अलग-अलग हो सकती है, इसलिए इस मशीन की रोपण पंक्ति की दूरी को समायोजित किया जा सकता है। इसलिए यह विभिन्न प्रकार की फसलों के लिए उपयुक्त है।

मक्का बोने की मशीन की बुआई की गहराई को बुआई के दौरान समायोजित किया जा सकता है। यह सुनिश्चित करता है कि बीज उद्भव दर 99% जितनी अधिक है।

एक मक्का बोने वाला यंत्र किस प्रकार की फसलों को संभाल सकता है, इसकी खोज करने के बाद, मक्का बोने की मशीन की संरचना को समझना महत्वपूर्ण है। यह ज्ञान इसकी रोपण क्षमताओं को अनुकूलित करता है।

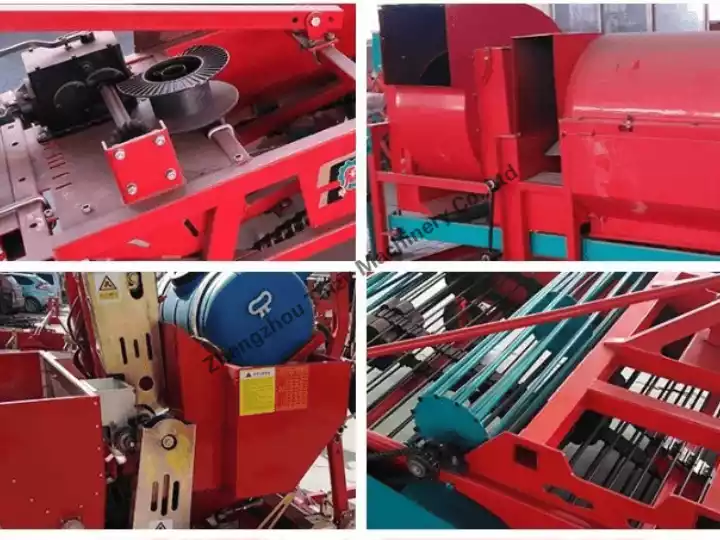

मक्का बोने की मशीन की संरचना

रोपण बॉक्स

पीसी सामग्री रोपण बॉक्स मजबूत और टिकाऊ है, और मोड़ना आसान नहीं है।

कॉर्न प्लांटिंग बॉक्स में अच्छी मज़बूती होती है। बकल धातु से बना होता है, सतह गैल्वेनाइज्ड होती है, और यह आसानी से जंग नहीं खाती है।

छिड़काव भाग

मक्का बीज बोने की मशीन के बॉडी को पहले ग्राइंडिंग करके और फिर उच्च तापमान पर बेक्ड पेंट लगाकर तैयार किया जाता है, जो समय के साथ मजबूत आसंजन और स्थायित्व सुनिश्चित करता है।

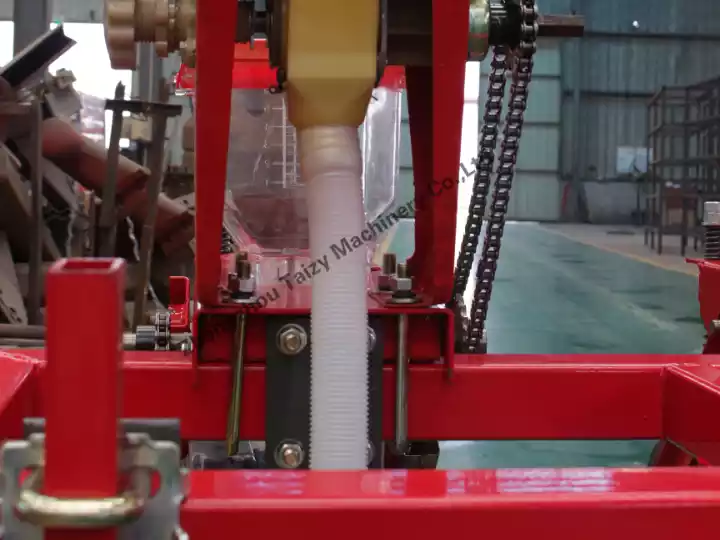

बुआई भाग

ऊंचाई को समायोजित किया जा सकता है. सीडर की बुआई की गहराई को सरल तरीके से समायोजित किया जा सकता है।

बुआई की गहराई और पंक्ति की दूरी को निर्देशों या वीडियो के अनुसार आसानी से समायोजित किया जा सकता है।

मकई बोने की मशीन की संरचना मकई के बीज के समान वितरण को सुनिश्चित करने में महत्वपूर्ण भूमिका निभाती है।

मक्के की समान रूप से बुआई कैसे करें?

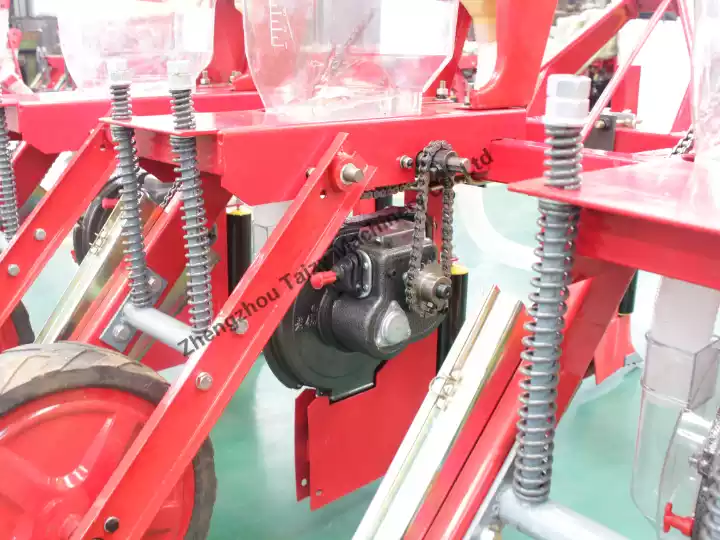

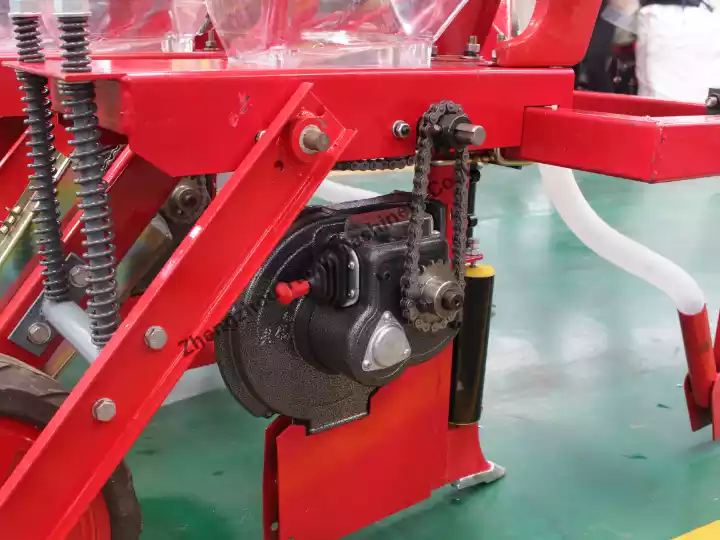

पूरी मशीन गियरबॉक्स के माध्यम से प्लांट स्पेसिंग को बदल सकती है, जो चार प्लांट स्पेसिंग का उत्पादन कर सकती है। जब तक गियरबॉक्स का ट्रांसमिशन अनुपात बदला जाता है, तब तक पूरी मशीन की प्रत्येक पंक्ति की प्लांट स्पेसिंग को बदला जा सकता है।

गियरबॉक्स ऑपरेटिंग लीवर रेडियल पेंडुलम और पेंडुलम व्हील के अक्षीय आंदोलन को एक साथ नियंत्रित करने की अनुमति देता है, जिससे तेज और सुविधाजनक संचालन सुनिश्चित होता है। गियरबॉक्स के सभी गियर स्टील से बने हैं और इनका कार्बराइजिंग उपचार किया गया है।

फ़्रेम को ज़मीन से उठा लिया जाता है. इससे आगे और पीछे के ओपनरों के बीच की दूरी बढ़ जाती है। परिणामस्वरूप, यह गर्मियों में गेहूं के भूसे की रुकावट को कम करता है।

मकई के बीजों का समान वितरण प्राप्त करने के लिए, मकई बोने की मशीन के विशिष्ट मापदंडों पर ध्यान देने से पहले परिचालन तकनीक आवश्यक है।

मकई बोने की मशीन के पैरामीटर

| नमूना | 2BYSF-2 | 2BYSF-3 | 2BYSF-4 | 2BYSF-5 | 2BYSF-6 | 2BYSF-8 |

| आकार | 1.57*1.3*1.2मी | 1.57*1.7*1.2मी | 1.62*2.35*1.2मी | 1.62*2.75*1.2मी | 1.62*3.35*1.2मी | 1.64*4.6*1.2मी |

| पंक्ति | 2 | 3 | 4 | 5 | 6 | 8 |

| पंक्ति रिक्ति | 428-570 मिमी | 428-570 मिमी | 428-570 मिमी | 428-570 मिमी | 428-570 मिमी | 428-570 मिमी |

| पौधों का अंतर | 140मिमी-280मिमी | 140मिमी-280मिमी | 140मिमी-280मिमी | 140मिमी-280मिमी | 140मिमी-280मिमी | 140मिमी-280मिमी |

| गहरी खाई | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी |

| निषेचन गहराई | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी | 60-80 मिमी |

| बुआई की गहराई | 30-50 मिमी | 30-50 मिमी | 30-50 मिमी | 30-50 मिमी | 30-50 मिमी | 30-50 मिमी |

| उर्वरक टैंक की क्षमता | 18.75L x2 | 18.75L x3 | 18.75L x4 | 18.75L x5 | 18.75L x6 | 18.75L x8 |

| सीडबॉक्स की क्षमता | 8.5एल x 2 | 8.5एल x 3 | 8.5एल x 4 | 8.5एल x 5 | 8.5एल x 6 | 8.5एल x 8 |

| वज़न | 150 किलो | 200 किलो | 295 किग्रा | 360 किग्रा | 425 किग्रा | 650 किग्रा |

| मिलान शक्ति | 12-18hp | 15-25hp | 25-40hp | 40-60hp | 50-80hp | 75-100hp |

| कड़ी | 3-उठाई | 3-उठाई | 3-उठाई | 3-उठाई | 3-उठाई | 3-उठाई |

मकई सीडर मशीन के पैरामीटर सीधे क्षेत्र संचालन के दौरान इसकी दक्षता और सटीकता को प्रभावित करते हैं, जिससे इष्टतम प्रदर्शन के लिए ट्रैक्टर के साथ प्रभावी समन्वय की आवश्यकता होती है।

मकई की बुआई की मशीन के लिए ट्रैक्टर के उपयोग की आवश्यकता होती है

मक्का बोने की मशीन का उपयोग ट्रैक्टर के साथ किया जाना चाहिए। इसे चलाने के लिए मकई बोने की मशीन को ट्रैक्टर से जोड़ें।

मकई बागान के विभिन्न मॉडलों के लिए अलग-अलग अश्वशक्ति वाले ट्रैक्टरों की आवश्यकता होती है। यह सुनिश्चित करता है कि ट्रैक्टर प्लांटर को शक्ति दे सकता है और चला सकता है।

मक्के की बुआई मशीन के साथ ट्रैक्टर का उपयोग करना मशीनीकृत बिजली पर इसकी निर्भरता को उजागर करता है, जो खेत संचालन के लिए आवश्यक है।

मक्का बोने की मशीन कैसे काम करती है?

1. मीटरिंग डिवाइस संरचना

मीटरिंग डिवाइस में एक गाइड व्हील, डायाफ्राम, डिवाइस बॉडी, स्कूप व्हील्स की पंक्तियाँ और एक डिवाइस कवर होता है। स्थिरता सुनिश्चित करने के लिए डिवाइस बॉडी और मीटरिंग डिवाइस कवर के बीच एक विभाजन स्थापित किया गया है।

2. बीज स्कूप व्हील स्थापना

मकई बीज स्कूप व्हील को गाइड व्हील पर स्थापित किया गया है, जिसमें पंक्ति व्हील और गाइड व्हील के बीच एक गोलाकार प्लेट लगाई गई है। सापेक्ष घूर्णन के दौरान जाम को रोकने के लिए उनके बीच लगभग 0.5 मिमी की निकासी होती है।

3. बीज भरने की प्रक्रिया

जैसे ही मशीन चलती है, बीज कवर के नीचे मीटरिंग डिवाइस में प्रवेश करते हैं। नीचे के भराव क्षेत्र में, स्कूप व्हील बीज से भर जाता है। उचित भराव सुनिश्चित करने के लिए स्कूप व्हील और गाइड व्हील दोनों दक्षिणावर्त घूमते हैं।

4. बीज की सफाई और नियमन

भराव क्षेत्र में, अतिरिक्त बीज स्कूप छेद से निकल जाते हैं और वापस भराव क्षेत्र में गिर जाते हैं। जब स्कूप व्हील मीटरिंग डिवाइस पर घूमता है, तो अतिरिक्त बीज हटा दिए जाते हैं, जिससे प्रति स्कूप केवल एक बीज सुनिश्चित होता है।

5. बीज विमोचन

जैसे ही स्कूप घूमता है, बीज केन्द्रापसारक बल और गुरुत्वाकर्षण द्वारा संबंधित गाइड व्हील खांचे में निर्देशित होते हैं। यह सुनिश्चित करता है कि प्रत्येक स्कूप बीज बोने वाले क्षेत्र में सटीक रूप से बीज जमा करता है।

6. बीज प्लेसमेंट

मीटरिंग उपकरण के खोल में खुले छिद्रों के माध्यम से बीजों का आवागमन जारी रहता है। वे ओपनर में गिर जाते हैं, जो मिट्टी में एक नाली बनाता है, जिससे बीज लगाने की प्रक्रिया पूरी हो जाती है।

यह समझना कि मकई बोने की मशीन कैसे संचालित होती है, कृषि पद्धतियों में इसके कई लाभों के बारे में जानकारी प्रदान करती है।

मक्का बोने की मशीन के फायदे

- उच्च बीजारोपण परिशुद्धता। सीडिंग डिवाइस में 80% से अधिक कण संख्या योग्यता सूचकांक के साथ उच्च सीडिंग परिशुद्धता होती है, जो सटीक और लगातार बीज रोपण सुनिश्चित करती है।

- हाई-स्पीड ऑपरेशन. सामान्य भराव के साथ उच्च गति पर काम करने में सक्षम, पौधों की दूरी कम से कम 20 सेमी होने पर 8 किमी/घंटा तक पहुंच जाती है, जिससे तेजी से और अधिक कुशल रोपण की अनुमति मिलती है।

- सटीक छिद्र रिक्ति. छिद्रों के बीच सटीक अंतर और समान पौध वितरण सुनिश्चित करता है, पौधों के बीच प्रतिस्पर्धा को कम करता है और जोरदार फसल विकास को बढ़ावा देता है, जिससे अधिक पैदावार होती है।

- सुविधाजनक गियरबॉक्स संचालन। गियरबॉक्स ऑपरेशन लीवर रेडियल पेंडुलम और पेंडुलम व्हील के अक्षीय आंदोलन दोनों को एक साथ नियंत्रित करता है, जिससे ऑपरेशन त्वरित और सुविधाजनक हो जाता है।

- टिकाऊ गियरबॉक्स घटक। गियरबॉक्स में सभी गियर उच्च गुणवत्ता वाले स्टील से बने होते हैं और लंबे समय तक चलने वाले प्रदर्शन को सुनिश्चित करते हुए बेहतर स्थायित्व के लिए कार्बोराइज्ड होते हैं।

- विश्वसनीय ट्रांसमिशन पार्ट्स। ट्रांसमिशन घटक उच्च गुणवत्ता वाले रोलिंग बियरिंग्स से बने होते हैं, जो विश्वसनीय प्रदर्शन प्रदान करते हैं और यह सुनिश्चित करते हैं कि मशीन सुचारू रूप से चले।

मकई बुआई मशीन के फायदे इसकी दक्षता और उत्पादकता लाभों को उजागर करते हैं, जो कृषि कार्यों में उत्पादकों के सामने आने वाली विभिन्न चुनौतियों का समाधान करते हैं।

मक्का बोने वाले किसानों की किन समस्याओं का समाधान करते हैं?

यह पूरी तरह से स्वचालित मक्का बोने की मशीन कृषि मशीनीकरण को बढ़ाती है। यह रोपण के लिए अधिक कारगर है. यह बिना किसी उपकरण या अर्ध-स्वचालित प्लांटर्स का उपयोग करने की अक्षमता और उच्च श्रम को समाप्त करता है।

उत्पादन क्षमता की समस्याओं के कारण मक्के की बुवाई के सर्वोत्तम चक्र को चूकने से बचें, जिससे मक्के के अंकुरण और विकास पर असर पड़ता है। इसके अतिरिक्त, हमारे पास अर्ध-स्वचालित मक्का बोने की मशीनें भी हैं, जो छोटे उत्पादन वाले मक्के की बुवाई के लिए बहुत उपयुक्त हैं।

मकई बागान मालिक रोपण प्रक्रिया के दौरान उत्पादकों के सामने आने वाली विभिन्न चुनौतियों का प्रभावी ढंग से समाधान करते हैं। सर्वोत्तम प्रदर्शन और दीर्घायु के लिए मक्का रोपण मशीन के सुझावों और रखरखाव को समझना भी उतना ही आवश्यक है।

मक्का रोपण मशीन की युक्तियाँ और रखरखाव

- प्रत्येक शिफ्ट के बाद मशीन को विभिन्न हिस्सों से मिट्टी और मलबा हटाकर अच्छी तरह साफ करें।

- प्रतिदिन सिलेंडर और लिफ्टर डिस्क से बचे हुए उर्वरक और बीज को साफ करें।

- नियमित रूप से कनेक्शनों की जांच करें और उन्हें कस लें; किसी भी ढीलेपन को तुरंत दूर करें।

- सुचारू संचालन के लिए घूमने वाले हिस्सों का निरीक्षण करें; आवश्यकतानुसार घिसे हुए घटकों को समायोजित करें या बदलें।

- ऑपरेशन के हर चार घंटे में स्प्रोकेट स्लॉट पर मक्खन लगाएं; चेन और फ्लाईव्हील को नियमित रूप से चिकनाई दें।

मक्का रोपण मशीन की युक्तियों और रखरखाव को समझना इसकी दीर्घायु और दक्षता सुनिश्चित करता है, यह निर्णय लेते समय महत्वपूर्ण विचार हैं कि सही मक्का रोपण मशीन कैसे खरीदी जाए।

मक्का बोने की मशीन कैसे खरीदें?

यदि आप इसे पढ़ रहे हैं, तो आप हमारी वेबसाइट पर पहुंच गए हैं जहां आप हमारी संपर्क जानकारी पा सकते हैं। वेबसाइट पर दिए गए संपर्क विवरण का उपयोग करके बेझिझक सीधे हमसे संपर्क करें, या संदेश अनुभाग में अपनी संपर्क जानकारी छोड़ दें।

हम आपको अपनी मशीनों के बारे में विस्तृत जानकारी शीघ्र भेजेंगे और जल्द ही आपसे संपर्क करेंगे। अपनी संचालन प्रक्रियाओं को कैसे लाभ पहुंचा सकते हैं, यह जानने के लिए अभी हमारी मशीनों के बारे में पूछताछ करने में संकोच न करें!