Broyeur à marteaux 9FQ | Broyeur de maïs

| Modèle | 9FQ-750 |

| Puissance (kW) | 22-30 |

| Poids (kg) | 850 |

| Capacité (kg/h) | 1500 |

| Marteau | 32 pièces |

| Dia du tamis | 1,2-3 mm |

| Taille du paquet (mm) | 1500*1000*1600 |

| Taille d'installation (mm) avec cyclone et moteur | 2000*1200*2300 |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

La série de broyeurs à marteaux 9FQ offre une solution efficace et adaptable pour le traitement des grains, pouvant accueillir des capacités allant de 100 à 3 000 kg/h pour s'adapter à une grande variété d'applications.

Équipées de systèmes de dépoussiérage à cyclone en option pour une efficacité accrue et disponibles avec des moteurs diesel ou électriques, ces machines excellent dans les zones où l'accès à l'électricité est limité.

Les tamis réglables permettent des tailles de particules personnalisées, ce qui rend le broyeur à marteaux 9FQ idéal pour traiter les céréales comme la farine de maïs et de soja dans les moulins à farine, les magasins familiaux et les entreprises agricoles.

Application de broyeur à marteaux

Applications polyvalentes

- Écrasez diverses céréales pour faire de la farine, notamment du maïs, du blé et du soja.

- Utiliser dans les fermes pour produire alimentation pour les bovins et les ovins.

- Traitez des cultures supplémentaires comme les coquilles d'arachide, le fourrage et la paille.

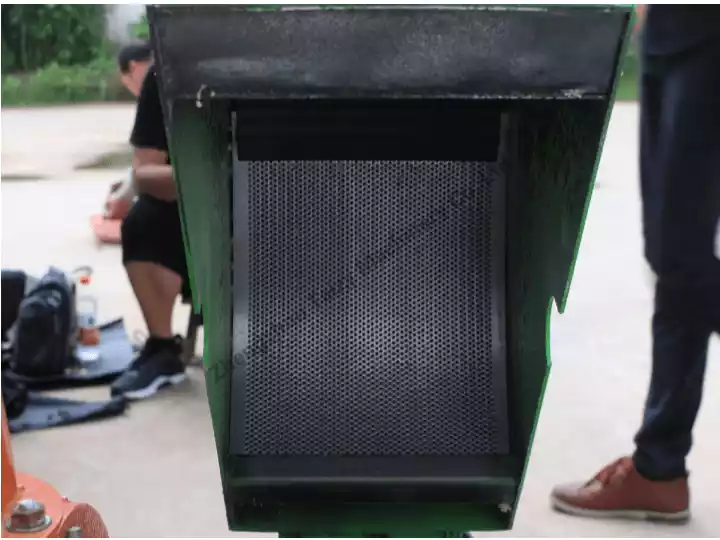

Caractéristique clé – tamis remplaçable

- Cette flexibilité permet à la machine d’exécuter efficacement plusieurs fonctions.

- La polyvalence de la machine provient de son tamis remplaçable, qui détermine la gamme de matériaux qu'elle peut traiter.

Finesse de machine de broyeur à marteaux 9FQ du maïs

Capacité de broyage :

- Réduit les matières premières à moins de 5 cm.

- Traite une large gamme de matières premières en différentes granulométries, telles que 1 mm-3 cm, 4 cm et 5 cm.

Mécanisme de broyage :

- Les matériaux sont introduits via l'orifice d'alimentation dans la cavité de concassage.

- L'arbre rotatif et le marteau à grande vitesse travaillent ensemble pour écraser rapidement le matériau.

Sélection de finesse :

- Les matériaux broyés répondant à la finesse souhaitée traversent le tamis et sont évacués.

- Les particules plus grosses continuent de circuler avec le flux d'air jusqu'à ce qu'elles soient finement broyées à la taille requise.

structure de la machine du broyeur à marteaux 9fq

- Principaux composants:

- Coque du dispositif d'alimentation.

- Arbre rotatif avec marteaux attachés.

- Écrans pour contrôler la taille et la finesse des matériaux.

- Pièces résistantes à l'usure pour plus de durabilité.

- Ventilateur à tirage induit qui sert également d'orifice de décharge.

- Mécanisme de broyage:

- La cavité de concassage comprend :

- Un arbre principal.

- Quatre arbres assortis fixés à l'arbre principal.

- 14 marteaux par petit arbre, soit un total de 56 marteaux.

- La cavité de concassage comprend :

- Contrôle de la finesse des matériaux:

- Un tamis situé sous l'arbre rotatif détermine la taille et la finesse des matériaux déchargés.

- Système de déchargement à grande vitesse:

- Le ventilateur à tirage induit facilite l'expulsion des matériaux broyés (par exemple les particules de sciure).

- Le fonctionnement à grande vitesse garantit une production efficace des matériaux.

Détails de la machine du broyeur à marteaux 9FQ

Marteau résistant à l'usure

Utilisant une technologie de traitement de trempe en acier au carbone épaissi, solide et durable, sa durée de vie est 4 fois supérieure à celle des marteaux ordinaires.

Moteur tout en cuivre

Le fil de cuivre à haute température est durable et plein de puissance.

Augmenter l'entrée

Solide et durable, facile à nourrir.

Soudage de précision

L'usine dispose de 20 ans de technologie de soudage professionnelle, d'une finition soignée et d'aucune fuite.

Vidéo de travail de la machine à broyeur à marteaux

Paramètres de la machine à broyer le maïs

| Modèle | Puissance (kW) | Puissance (HP) | Poids (kg) | Capacité (kg/h) | Marteau | Dia du tamis | Taille du paquet (mm) | Taille d'installation (mm) avec cyclone et moteur |

| 9FQ-320 | 2.2 | 5 | 50 | 100 | 16 pièces | 0,5-5 mm | 500*300*600 | 500*300*600 |

| 9FQ-360 | 5.5 | 8 | 120 | 150 | 24 pièces | 0,5-5 mm | 1100*600*1200 | 1500*1000*1900 |

| 9FQ-420 | 11 | 15 | 200 | 300 | 24 pièces | 1,2-3 mm | 1200*800*1900 | 1500*1000*1900 |

| 9FQ-500 | 11 | 20 | 300 | 500 | 24 pièces | 1,2-3 mm | 1200*800*1300 | 1500*1000*1900 |

| 9FQ-600 | 18.5-22 | 30 | 500 | 1000 | 32 pièces | 1,2-3 mm | 1500*900*1500 | 2000*1100*2300 |

| 9FQ-750 | 22-30 | 35 | 850 | 1500 | 32 pièces | 1,2-3 mm | 1500*1000*1600 | 2000*1200*2300 |

| 9FQ-800 | 37 | 45 | 1000 | 2000 | 40 pièces | 1,2-5 mm | 1500*1200*1600 | 2000*1300*2300 |

| 9FQ-1000 | 45-55 | 75 | 1200 | 3000 | 64 pièces | 1,2-5 mm | 1500*1300*1800 | 2000*1400*2300 |

Avantages de la machine de broyeur à marteaux 9FQ

Efficacité énergétique :

- Consomme moins d'énergie que les broyeurs à disques, car le moteur électrique entraîne uniquement les marteaux au lieu d'un disque abrasif.

Léger et efficace :

- Conçu pour une efficacité de travail élevée tout en conservant une structure compacte et légère.

Polyvalence des matières premières :

- Épis et grains de maïs.

- Pommes de terre en tranches ou fruits à pain d'Afrique.

Remplacement facile du tamis :

- Vidéo pédagogique complète et plusieurs tailles de tamis fournies pour répondre aux exigences des clients.

- Comprend des tamis facilement remplaçables pour contrôler la taille de sortie.

Mobilité et flexibilité :

- Peut être déplacé, débarqué ou fixé selon les exigences opérationnelles.

Utilisation conviviale :

- Simple à utiliser, permettant à une seule personne de gérer efficacement les tâches de broyage des grains.

Fonctionnalités de sécurité améliorées :

- Équipé d'un capot de sécurité pour un fonctionnement sécurisé, garantissant une production sûre et confiante.

Prix de la machine à broyer le maïs

Le prix d’une rectifieuse de maïs reflète sa nature personnalisable et son adaptabilité aux divers besoins opérationnels. Des facteurs tels que la capacité de la machine, le type de moteur (diesel ou électrique), les fonctionnalités supplémentaires et la taille des tamis contribuent à sa fourchette de prix.

Dans notre entreprise, nous comprenons l’importance des solutions sur mesure et encourageons les clients à nous contacter pour connaître les détails des tarifs. En partageant vos besoins spécifiques, nous pouvons vous fournir des recommandations personnalisées et vous assurer de trouver une machine qui répond efficacement à vos besoins. N'hésitez pas à nous contacter pour un devis personnalisé et des conseils d'experts !

Conclusion

Engagé à fournir une qualité de premier ordre, notre broyeur de maïs témoigne de son efficacité, de sa commodité et de sa faible consommation d'énergie.

Nous sommes très fiers d’accueillir les demandes de renseignements et les achats de clients de divers secteurs. Cet équipement performant et convivial est un outil indispensable dans votre flux de transformation du maïs.

Dans le cadre de notre gamme de produits, nous proposons également d'autres machines à maïs telles que machine à fabriquer des semoules de maïs et machine à moudre la farine de maïs. N'hésitez pas à consulter notre équipe professionnelle à tout moment pour obtenir des informations détaillées sur nos produits.