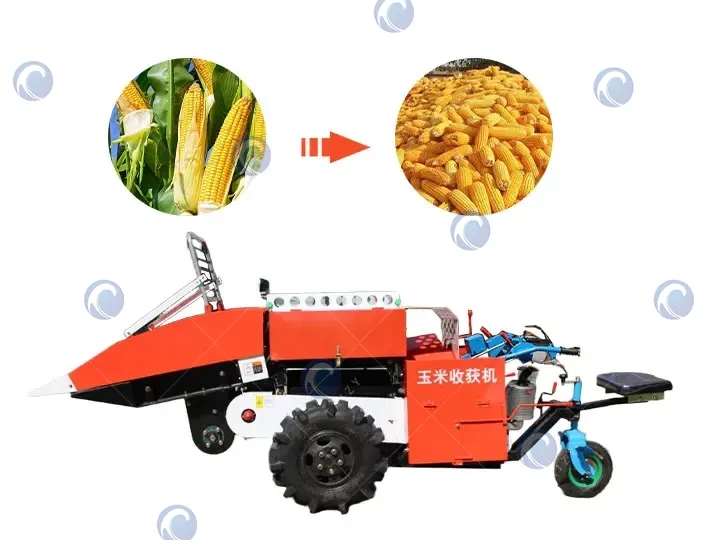

آلة طحن الذرة 9fq المصدرة إلى ليبيا

عميلنا، وهو عملية زراعية في منطقة ريفية، قام مؤخرًا بشراء آلة طحن الذرة 9FQ لمعالجة مجموعة متنوعة من المواد الخام إلى علف للماشية والأغنام والدواجن.

لقد كانوا مهتمين بشكل خاص بتحسين كفاءة إنتاج الأعلاف وعمليات طحن الدقيق، وقد لجأوا إلى مطحنة المطرقة الخاصة بنا نظرًا لتعدد استخداماتها وكفاءتها.

ماكينة طحن الذرة أتطبيق

أثبتت آلة طحن الذرة 9FQ أنها قابلة للتكيف بشكل كبير مع احتياجات العميل. الآلة قادرة على معالجة مجموعة واسعة من المواد الخام، بما في ذلك الحبوب مثل الذرة والقمح وفول الصويا، مما يجعلها مثالية لكل من إنتاج الدقيق وعلف الحيوانات.

بالإضافة إلى ذلك، فإن الآلة فعالة في سحق المواد مثل قش الفول السوداني والأعلاف والقش، التي تستخدمها المزرعة لصنع علف مغذي للماشية.

تأتي مرونة الآلة من الشبكات القابلة للتبديل، التي تسمح للعميل بضبط حجم الناتج، مما يضمن استخدامها في كل من الطحن الناعم وإنتاج العلف الخشن.

من خلال تغيير الشاشات، يمكن للعميل التبديل بسهولة بين إنتاج الدقيق الناعم أو الجسيمات الأكبر حجمًا لتغذية الحيوانات، مما يزيد من إمكانات الماكينة.

المعالجة والكفاءة

أثناء التشغيل، يقوم العميل بتغذية المواد الخام في حجرة السحق، حيث يعمل العمود الدوار والمطرقة معًا لسحق المواد بسرعة.

على سبيل المثال، عند سحق الذرة، قامت الآلة بتقليل حجم المادة الخام إلى أقل من 5 سم، وهو ما يعد مثاليًا لمزيد من المعالجة إلى دقيق أو علف. يمكن للآلة طحن المواد إلى أحجام متفاوتة، تتراوح من 1 مم إلى 3 سم أو 4 سم أو 5 سم.

تخلق عملية الطحن عالية السرعة احتكاكًا، مما يولد الحرارة، ويقتل البكتيريا الضارة بشكل فعال ويجعل العلف المعالج أكثر تغذية وأسهل في الهضم للماشية.

ثم يتم دفع المادة عبر الشبكة، وإذا تم الوصول إلى درجة النعومة المطلوبة، تخرج من منفذ التفريغ. خلاف ذلك، تستمر في الدوران حتى يتم تحقيق الحجم المثالي.

النتائج والفوائد

منذ تنفيذ آلة طحن الذرة 9FQ، شهد العميل تحسنًا كبيرًا في كل من جودة وكفاءة إنتاج العلف.

وقد أتاحت لهم القدرة على التبديل بسهولة بين الدقيق الناعم وجزيئات العلف الأكبر حجمًا تلبية الاحتياجات الغذائية المتنوعة لماشيتهم، في حين أدت العملية عالية السرعة إلى تقليل وقت الإنتاج بشكل كبير.

كما لاحظت المزرعة سهولة صيانة الآلة، حيث يمكن استبدال الشبكات بسرعة لضبط حجم الناتج للآلة. هذه الميزة زادت من مرونتها، مما يسمح للعميل بالاستمرار في معالجة مجموعة متنوعة من المواد بكفاءة وبتكلفة فعالة.

خاتمة

أثبتت آلة طحن الذرة 9FQ أنها إضافة لا تقدر بثمن لعملائنا. من خلال تقديم كفاءة عالية وتنوع في الاستخدام، فقد حسنت بشكل كبير عملية إنتاج الأعلاف، حيث توفر علفًا حيوانيًا عالي الجودة وسهل الهضم، مع تعزيز الإنتاجية الإجمالية.

أصبح العميل الآن قادرًا على معالجة مجموعة واسعة من المواد الخام، مما يضمن قدرته على تلبية الاحتياجات الغذائية لماشيته على مدار العام.