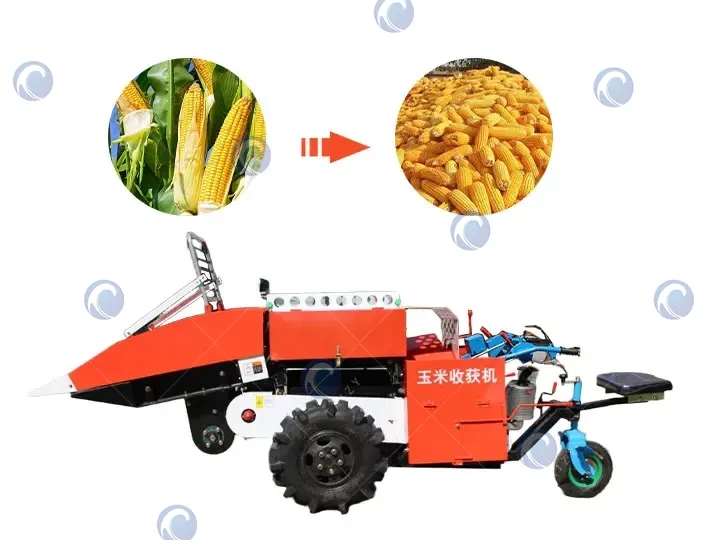

What is the fresh corn cutter machine?

The fresh corn cutter machine is an indispensable machine in agriculture and the food processing industry. Corn often needs to be processed into different shapes based on specific needs. For a long time, corn cutting has relied on manual labor, which is not only inefficient but also difficult to ensure a neat cut.

The emergence of the corn cutter machine solved these problems. It is a device specifically designed to process corn cobs and achieve standardized cutting. It is widely used in agricultural product processing workshops, catering pre-processing, and other scenarios. Its high efficiency and precision make it a key tool for improving corn processing efficiency.

Definition of fresh corn cutter machine

Essentially, the corn cutter is a special cutting device designed specifically for corn cobs. Its core function is to quickly and evenly cut whole corn cobs into individual segments according to a preset length (typically 2.5-7 cm, adjustable).

Compared to traditional manual cutting methods like kitchen knives and sickles, the maize cutter breaks free from the limitations of relying on experience and feel. Through mechanization, it standardizes the cutting process, meeting consistent cutting needs for both small-scale household processing and large-scale production.

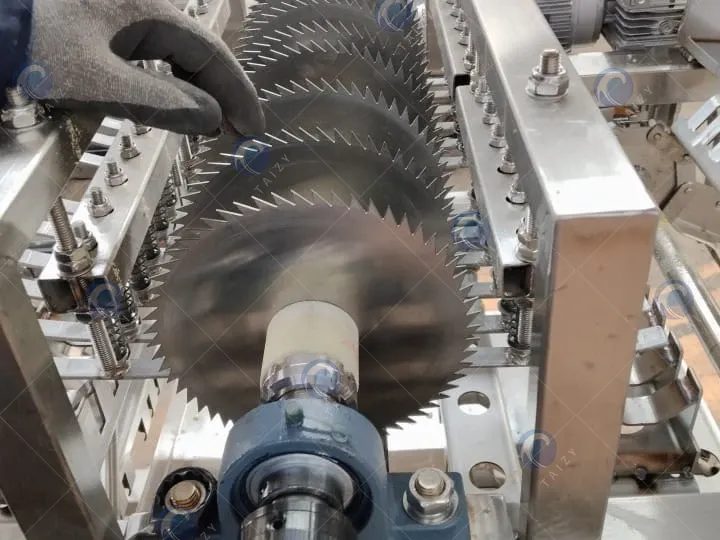

Working principle of corn cutting machine

- Corn conveying: The operator places whole corn cobs onto the corn cutter’s conveyor belt, which transports the cobs to the cutting area at a constant speed.

- Tool adjustment: The cutting system’s tools are adjusted in advance based on the desired corn segment length.

- High-speed cutting: The drive motor drives the adjusted cutters at high speed, allowing them to cut instantly, ensuring a smooth cut.

- Automatic discharging: The cut corn segments fall from the conveyor belt to the discharge chute below.

Application scenarios of corn cutter

The fresh corn cutter machine is not a “single-purpose” device, but covers multiple scenarios from agricultural production to food processing according to the needs of different users, becoming a “good helper” to improve efficiency.

- Agricultural product processing: When making vacuum-packed corn cobs, canned corn, and hominy porridge ingredients, corn cobs need to be cut into uniform lengths. The sweet corn cutter machine ensures consistent lengths.

- Food processing: For example, frozen corn manufacturers need to cut, clean quickly, and freeze large quantities of corn cobs. Corn cutters can be used in conjunction with corn cleaning machine and quick-freezing machines to automated production.

- Catering: Some large cafeterias and chain restaurants also use electric maize cutter for pre-processing corn ingredients (for example, making corn and pork rib soup or roasted corn cobs), reducing manual labor in the kitchen and improving meal preparation efficiency.

conclusion

The fresh corn cutter machine not only solves the problems of manual cutting, such as low efficiency, large errors, and high costs, but also provides strong support for the standardization and large-scale development of the corn industry chain. If you are interested in this machine, contact us immediately for more information about it.