Price of stainless steel grinding mill

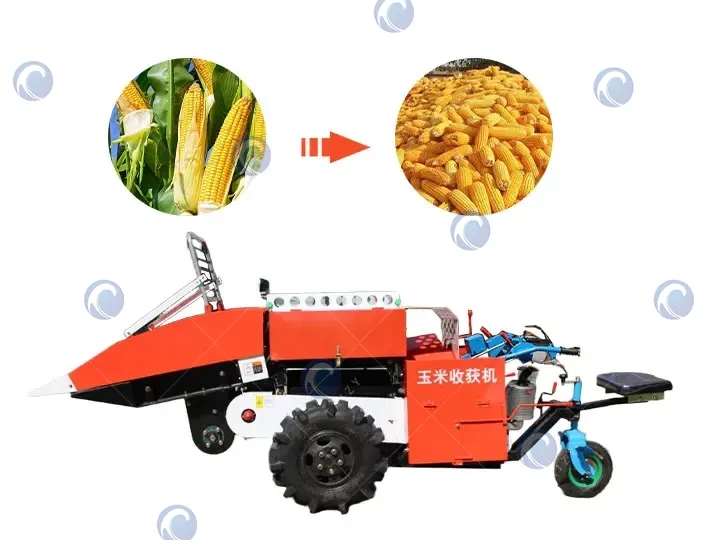

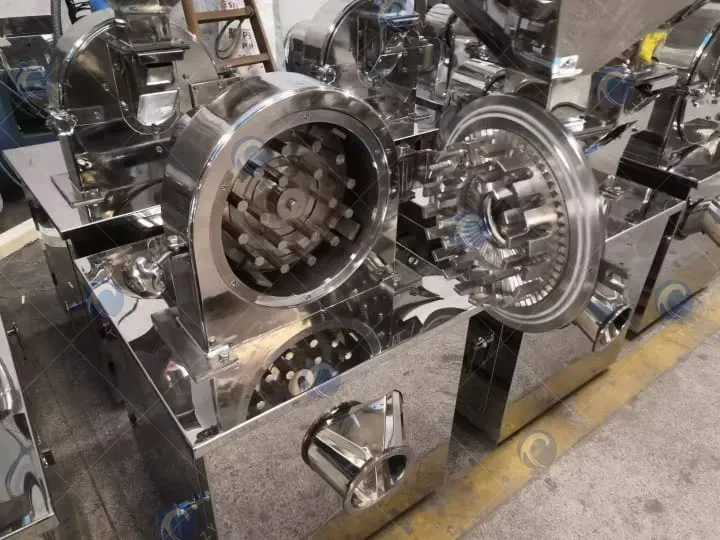

The stainless steel grinding mill is widely used in kitchens, restaurants, and industrial production. Its primary function is to grind various raw materials, such as corn, wheat, coffee beans, and chili peppers, into powder.

The price of the stainless steel milling machine is influenced by various factors, including the material and function, as well as the machine model, degree of automation, and efficiency.

Main factors affecting the price of grinder flour mill

The price of the stainless steel grinding mill is affected by many factors, including the following aspects:

- Materials and craftsmanship: The choice of stainless steel (such as 304 and 316 stainless steel) directly impacts the equipment’s durability, corrosion resistance, and cost.

- Machine model: Different models vary significantly in their functionality and application range. Higher-end models may include more features, such as a finer grinding system, which increases production costs.

- Degree of automation: The degree of automation is a key factor influencing the price of a small mill. Manual or semi-automatic small mills are relatively low-priced. However, fully automatic equipment, due to its intelligent operation and automated control, can command significantly higher prices.

- Efficiency: More efficient equipment is generally more expensive. More efficient equipment requires a more powerful power system, which in turn leads to a higher price.

Suggestions for purchasing stainless steel flour mill machine

- When choosing the stainless steel grinding mill machine, you first need to decide on the type of equipment based on the intended use scenario. For example, if you are using it in the catering industry or a small business, you should consider equipment with a high degree of automation to improve work efficiency.

- The quality of the equipment directly affects its service life and working efficiency. Choosing high-quality stainless steel materials, such as 304 or 316 stainless steel, can ensure that the equipment is corrosion-resistant, durable, and adaptable to different working environments.

- Choosing the right supplier is an important part of ensuring the quality of the machine and after-sales service. A high-quality supplier can not only provide high-quality equipment, but also provide professional after-sales service.

Why choose us as your supplier?

If you’re looking for a high-quality stainless steel grinding mill, Taizy is your ideal choice. As a professional agricultural equipment supplier, we offer a wide variety of equipment suitable for a variety of agricultural and commercial needs. Our machines are not only of superior quality but also highly regarded and trusted by numerous customers worldwide.

Whether you’re a home user or an industrial manufacturer, Taizy can provide the most suitable solution, ensuring efficient and stable performance. We have an extensive international customer base and have received positive feedback from customers around the world. You can rest assured that you will be able to choose our equipment and enjoy the guarantee of high-quality products and services.

Conclusion

The price of stainless steel grinding mills varies widely, influenced by a variety of factors, including material, brand, model, degree of automation, and operating efficiency. Consumers can choose the right product based on their budget and needs. If you’d like more detailed pricing, contact us today for a free consultation!