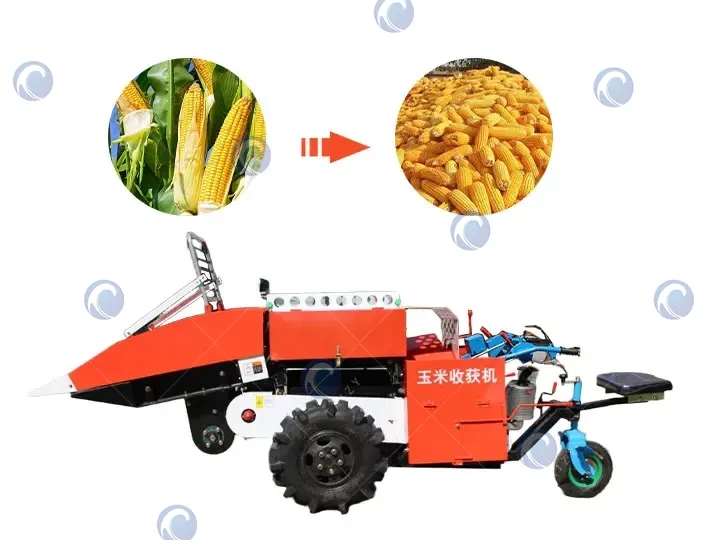

Growing demand for fresh corn sheller in the United States

In the United States, fresh corn is one of the most popular crops, widely used in the production of canned foods, frozen vegetables, and ready-to-eat snacks. With the continued development of the food processing industry, businesses are increasingly demanding efficient fresh corn shellers.

Reasons for the increased demand for fresh corn thresher

Compared to traditional manual threshing methods, fresh corn threshers offer significant advantages:

- High efficiency: The fresh corn thresher can thresh large quantities of corn in a short time, greatly increasing production capacity.

- Low loss: The machine operates smoothly, resulting in a high percentage of intact corn kernels and an aesthetically pleasing appearance.

- Hygiene and safety: The sweet corn sheller is typically made of stainless steel, avoiding contamination from human contact and meeting food safety standards.

- Labor savings: The machine can replace heavy manual labor, reducing production costs and increasing automation.

These advantages have made the fresh corn sheller increasingly popular in food processing plants, agricultural cooperatives, and farms in the United States.

Application of sweet corn sheller in the United States

Fresh corn shellers are suitable for diverse applications, covering nearly the entire corn processing chain:

- Food processing plants: It provides pre-processing services for products such as canned corn, frozen corn kernels, and corn salad.

- Agricultural processing bases: The fresh corn sheller enables bulk processing of fresh corn, enhancing processing efficiency.

- Food service and fast-food industries: The sweet corn threshing machine provides efficient ingredient preparation for fast-food establishments and canning factories.

- Agricultural cooperatives and farms: It enables farmers to mechanize the shelling process, reducing labor requirements.

How to choose fresh corn sheller machine?

Selecting the right machine is essential for faster and more efficient production. When purchasing the sweet corn sheller, users should consider the following factors:

- Production capacity requirements: Businesses should choose an appropriate capacity range based on their daily processing volume.

- Machine materials: The fresh corn shelling machine is primarily used in food processing, so attention should be paid to the materials used in construction.

- Power source: Customers can choose between electric or diesel-powered models to suit different operating environments.

- Supplier Selection: Customers are advised to choose suppliers with proven experience and comprehensive after-sales service for the fresh corn thresher.

Conclusion

As the U.S. food processing industry continues to expand and automation levels rise, the market demand for the fresh corn sheller remains steadily growing. The sweet maize threshing machine not only enhances production efficiency but also helps businesses maintain a competitive edge in the market.

If you are seeking reliable and efficient fresh corn shelling solutions, contact us today. We provide professional equipment and comprehensive after-sales support.