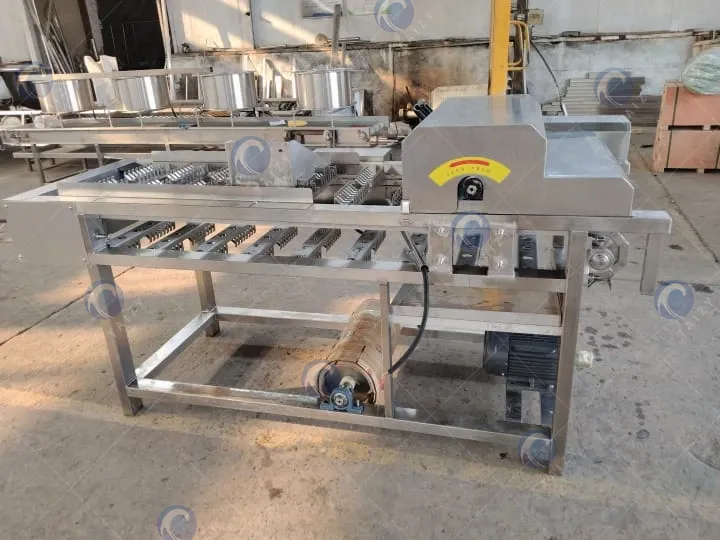

Sweet corn cutting machine sent to Vietnam

The corn cutting machine can rapidly process maize into corn segments of consistent length. Taizy corn cutter is very efficient, which can reach 1500-3000 cobs per hour. The processed corn can be used for canning, snack processing, quick-frozen food making, etc. Therefore, maize cutting machines are popular in the food processing industry and the catering industry. It has been exported to many countries. Recently, our corn cutter machine was sent to Vietnam.

Customer background and needs

Our customer runs a food processing factory in Vietnam. The factory mainly processes crops such as corn and sweet potatoes. Its products include quick-frozen corn segments and canned corn. Our client wanted to expand the production scale. However, the factory’s manual corn cutting process presented three major drawbacks:

- Low efficiency: Ten workers could only cut an average of 800kg of corn per day, making it difficult to meet the expansion requirements.

- Mismatched specifications: Manually cut corn segments had large length variations, leading to substandard finished products.

- High costs: Labor costs in Vietnam have been rising year by year, with monthly labor costs for corn cutting alone accounting for 35% of total costs.

Therefore, the customer came to us and clearly stated that they needed a corn cutter machine that could achieve standardized cutting, improve efficiency, and reduce labor costs.

Our solution

In response to customer needs, we recommend Taizy corn cutting machine, which has the following advantages:

- Compared to manual operation, the corn cutter offers greater precision, ensuring consistent corn lengths. Errors are kept to a minimum, significantly improving the smoothness of the cut.

- The machine can process 350 kilograms of corn per hour and can operate continuously, significantly improving production efficiency.

- The machine requires only one operator, saving nine workers’ wages per month, which translates to a 30% annual reduction in labor costs.

Delivery and shipping

We introduced the details of the corn cutter and its advantages to the customer. The customer expressed satisfaction and decided to place an order. After the customer paid the deposit, we immediately began production. After the corn cutting machine was completed, we sent the customer photos and videos of the machine. After the customer was satisfied, we shipped the corn cutter to Vietnam.

Customer feedback

The customer immediately put the machine to use upon receipt. A month later, we received his feedback. He stated that the efficiency and performance of the corn cutter exceeded his expectations. The corn cutting process not only minimized errors but also achieved high production efficiency, saving them significant time and manpower. The machine resolved his challenges and enabled him to successfully expand his food processing plant.

This success story shows the importance of automated machines in modern production. If you need the corn cutting machine, you can contact us for more information.