Forage cutter machine with kneading

| Brand | Taizy |

| Model | 9ZR-2.5T, 9ZR-3.8A, 9ZR-4.8T,9ZR-8, 9ZR-4.8C, etc. |

| Power | 3-11kw |

| Weight | 67-320kg |

| Capacity | 2500-8000kg/h |

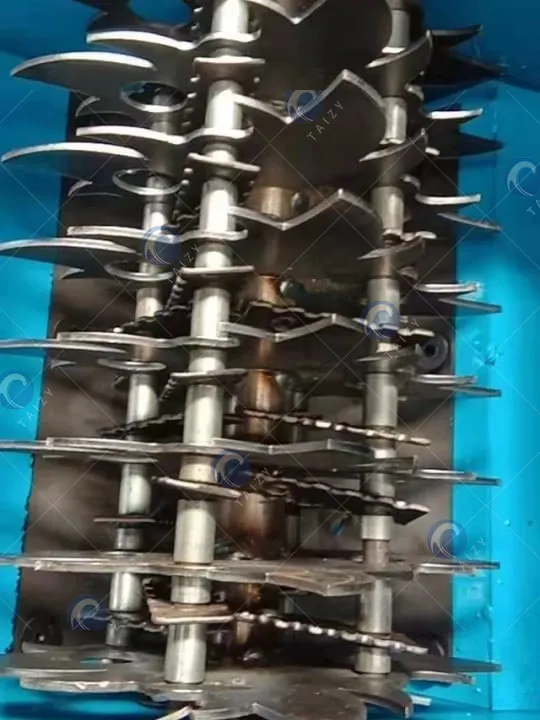

| Application | Alfalfa, corn straw, bean straw, peanut straw, sugarcane leaf, etc. |

You can now ask our project managers for technical details

This forage cutter machine is a silage processing device that integrates chopping and kneading functions. It can quickly cut and knead raw materials such as hay and straw, making the final feed more delicate, soft, and easier for ruminants to chew and digest.

Our chaff cutting machine features high efficiency, with cutting capacity ranging from 2,500 to 8,000 kg per hour. It can be equipped with three power options: electric motor, diesel engine, or gasoline engine, accommodating requirements across different regions.

Advantages of silage cutting machine

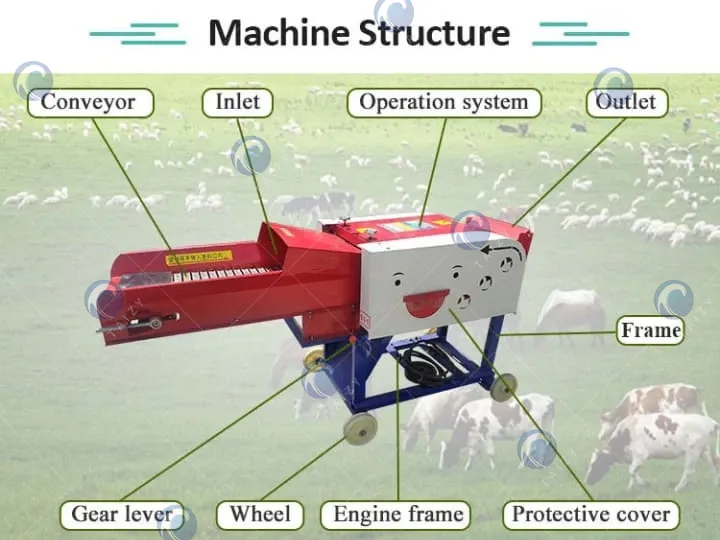

- Refined finished product: Our forage cutter machine uses horizontal blades for cutting and then serrated blades for pulverizing, transforming large pieces of feed into soft, fibrous shreds, making it more suitable for ruminants.

- Wide application: Taizy chaff cutting machine can process a variety of plant materials, including hay, alfalfa, leaf hay, corn stalks, bean stalks, rice straw, peanut stalks, and sugarcane stalks.

- Flexible use: The silage cutter’s cutting length can be adjusted via long and short gears to meet different feeding needs.

- Easy mobility: It is equipped with four wheels and with optional large pneumatic tires, making it easy to move in the field.

- Multiple power options: The hay chopping machine can be equipped with an electric motor, gasoline engine, or diesel engine to adapt to different regions and outdoor environments.

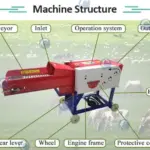

Main structure of forage cutter machine

This chaff cutter has a very simple structure, consisting of conveyor, inlet, operation system, gear lever, wheel, engine frame, and outlet. The operation system mainly consists of the cutting and kneading sections.

Types of chaff cutters for sale

This hay cutter comes in two types: Automatic hay cutters and split-type hay cutters.

- Automatic chaff cutter: Its cutting and shredding sections are inseparable.

- Split-type chaff cutter: This chaff cutter has separate cutting and kneading sections. For larger pieces, disassemble and lift the kneading part. For finer pieces, put the kneading part.

How does hay chopping machine work?

After the raw materials enter the forage cutter machine, they are initially cut by a high-speed rotating flat blade, which cuts the hay, straw, and other materials into large pieces or short strips.

Then, these chopped materials are further processed by serrated blades through kneading, making the hay into a softer and finer shredded product, which is more suitable for ruminants such as cattle and sheep to chew and digest.

Application of silage shredding machine

The forage cutter machine has a wide range of applications, capable of cutting various dry and wet materials, such as hay, alfalfa, sugarcane, corn stalks, bean stalks, rice straw, peanut stalks, and other fibrous crops, meeting diverse feeding needs.

Due to its uniform output and good palatability, the chaff cutting and kneading machine is widely used in livestock farms, family farms, cooperatives, feed processing plants, silage processing bases, and agricultural straw recycling projects.

Technical parameters of chaff cutter machine

The parameters of automatic silage cutting machine are as follows:

| Model | 9ZR-2.5T | 9ZR-380A | 9ZR-3.8B | 9ZR-4.8T | 9ZR-6.8 | 9ZR-8 |

| Power | 3-4.5kw | 3-4.5kw | 3-4.5kw | 5.5kw | 7.5kw | 11kw |

| Capacity | 2500kg/h | 3800kg/h | 3800kg/h | 4800kg/h | 6800kg/h | 8000kg/h |

| Size | 1350*490*750mm | 1650*550*900mm | 1750*550*900mm | 1750*600*930mm | 2283*740*1040mm | 3400*830*1200mm |

| Weight | 67kg | 88kg | 93kg | 116kg | 189kg | 320kg |

The specifications for the split-type silage shredder are as follows:

| Model | 9ZR-3.8C | 9ZR-4.8C |

| Power | 3-4.5kw | 5.5kw |

| Capacity | 3800kg/h | 4800kg/h |

| Size | 1750*550*900mm | 1950*600*9300mm |

| Weight | 94kg | 112.5kg |

Price and buying guide for grain straw chopper

The price of the forage cutter machine is influenced by a variety of factors. The main factors include the machine’s output capacity, the material and number of blades, whether it has a shredding function, and the presence of casters. Higher output and more advanced configurations will result in a higher price.

When purchasing the chaff cutter, choose a model based on your actual needs. Focus on blade material, machine thickness, power type, output efficiency, and whether cutting length is adjustable. It’s best to buy from reputable manufacturers with reliable after-sales service to ensure stable long-term use.

Successful case of Taizy silage cutting machine

250 units 9ZR-2.5t forage cutter machines sent to Uganda

A Ugandan customer specializing in agricultural and livestock equipment distribution ordered 250 9ZR-2.5T hay choppers from us to supply local small and medium-sized cattle and sheep farmers.

After the equipment was put into use, the customer reported that the machine operates stably and produces uniform output, significantly improving hay processing efficiency. It has been well-received by farmers and has helped the customer enhance their market competitiveness.

Contact us now to start your project!

As an efficient feed processing machine, the forage cutter machine plays an important role in livestock farming, silage production, and straw recycling. It helps improve processing efficiency, enhance feed quality, and reduce labor costs, providing reliable support for farmers and ranchers.

In addition, we offer a range of silage equipment, including silage harvester and silage baler, which can be combined to create efficient feed processing solutions. Contact us for more equipment details and customized options to make your livestock farming easier and more efficient!